How to solve the leakage of pipe joints?(tube fittings/hose fittings) Which pipe joint is strong

Luna

2022-03-23 14:33:39

How to solve the leakage of pipe joints?(tube fittings/hose fittings)

Which pipe joint is stronger? Pipe joints tested for no leaks

Jiangsu Yicheng Fluid Equipment Co.,Ltd, give you best fluid connecting solution.

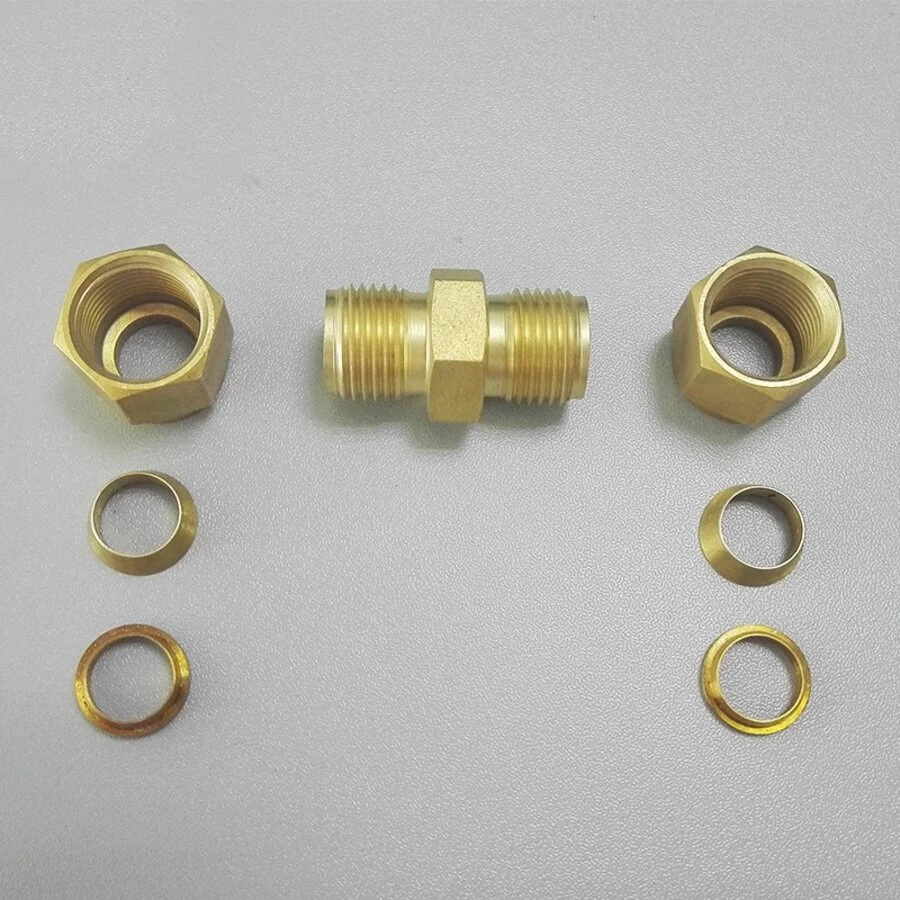

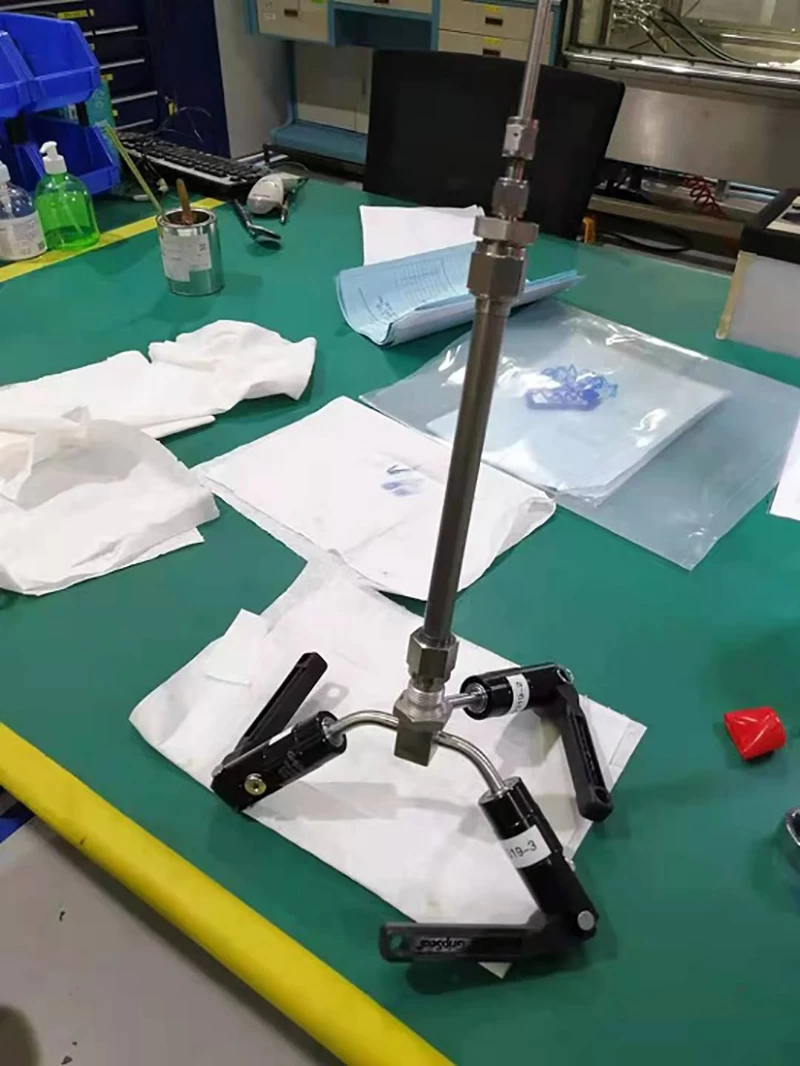

1. For the ferrule type pipe joints, most of the pipes are subjected to a large external force or impact force, which causes the ferrule to become loose or the end face of the pipe is deformed to cause leakage. Whether the end is in good condition and the compression degree of the ferrule nut, etc., and also eliminate the external force of the pipeline. 2. For flared pipe joints, mostly due to excessive flaring, unsatisfactory quality or repeated disassembly, resulting in leakage of flared deformation or cracks, at this time, the front end can be cut off and flared again.

The key to the joint in use is to ensure that the connection is firm and the sealing is reliable. In other words, it is stipulated that the pipelines are firmly connected to each other, and the tightness must be ensured so that no leakage occurs. But as far as the application of the joint is concerned, it is a common failure problem where the leakage advantage is very common. Which pipe joint is better, so it is recommended that customers understand how to deal with the joint leakage problem?

Regarding the solution to the leakage problem of the joint, the customer must first establish it, but the problems of the hydraulic transmission system are all very professional problems, so be sure to find a professional. Therefore, in the case of finding that the joint leaks, it is not necessary to disassemble and assemble the joint at will. The appropriate method is to first turn off the system software, stop running the application, and then immediately contact professional technicians for inspection and maintenance.

For the actual joint leakage solution, which one is better depends on the actual joint type and the specific leakage situation. According to the type of joint, do the corresponding inspection to establish the direct cause of leakage. A reasonable solution can then be found to ensure that the leak is completely eliminated and prevent similar problems from recurring in the future. Compression fittings are affordable.

From the perspective of how to deal with leakage problems of various joints, if it is a place where the "о" ring is used against the inner hole. It is usually necessary to re-select the "о" ring with the same diameter and a thicker cross-section. The latter one is to drill or cut the production process according to the sealing plan containing the groove to reduce the depth of the groove and let the "о" ring. ” ring again and again has a sufficient amount of elastic deformation.

If there is leakage at the joint of acid and alkali resistant rubber sheet, wool felt, alloy steel cardboard, gasket or sealant, no matter what the material is, the hydraulic seal should be checked first. Check whether the seal is damaged, deformed, aging and surface roughness is too large, and use matching countermeasures to solve the problem according to the tested joint.

Which pipe joint is stronger? Pipe joints tested for no leaks

Jiangsu Yicheng Fluid Equipment Co.,Ltd, give you best fluid connecting solution.

1. For the ferrule type pipe joints, most of the pipes are subjected to a large external force or impact force, which causes the ferrule to become loose or the end face of the pipe is deformed to cause leakage. Whether the end is in good condition and the compression degree of the ferrule nut, etc., and also eliminate the external force of the pipeline. 2. For flared pipe joints, mostly due to excessive flaring, unsatisfactory quality or repeated disassembly, resulting in leakage of flared deformation or cracks, at this time, the front end can be cut off and flared again.

The key to the joint in use is to ensure that the connection is firm and the sealing is reliable. In other words, it is stipulated that the pipelines are firmly connected to each other, and the tightness must be ensured so that no leakage occurs. But as far as the application of the joint is concerned, it is a common failure problem where the leakage advantage is very common. Which pipe joint is better, so it is recommended that customers understand how to deal with the joint leakage problem?

Regarding the solution to the leakage problem of the joint, the customer must first establish it, but the problems of the hydraulic transmission system are all very professional problems, so be sure to find a professional. Therefore, in the case of finding that the joint leaks, it is not necessary to disassemble and assemble the joint at will. The appropriate method is to first turn off the system software, stop running the application, and then immediately contact professional technicians for inspection and maintenance.

For the actual joint leakage solution, which one is better depends on the actual joint type and the specific leakage situation. According to the type of joint, do the corresponding inspection to establish the direct cause of leakage. A reasonable solution can then be found to ensure that the leak is completely eliminated and prevent similar problems from recurring in the future. Compression fittings are affordable.

From the perspective of how to deal with leakage problems of various joints, if it is a place where the "о" ring is used against the inner hole. It is usually necessary to re-select the "о" ring with the same diameter and a thicker cross-section. The latter one is to drill or cut the production process according to the sealing plan containing the groove to reduce the depth of the groove and let the "о" ring. ” ring again and again has a sufficient amount of elastic deformation.

If there is leakage at the joint of acid and alkali resistant rubber sheet, wool felt, alloy steel cardboard, gasket or sealant, no matter what the material is, the hydraulic seal should be checked first. Check whether the seal is damaged, deformed, aging and surface roughness is too large, and use matching countermeasures to solve the problem according to the tested joint.