YC-LOK ferrule tube fittings sealing & leakage

Luna

2021-08-20 14:36:41

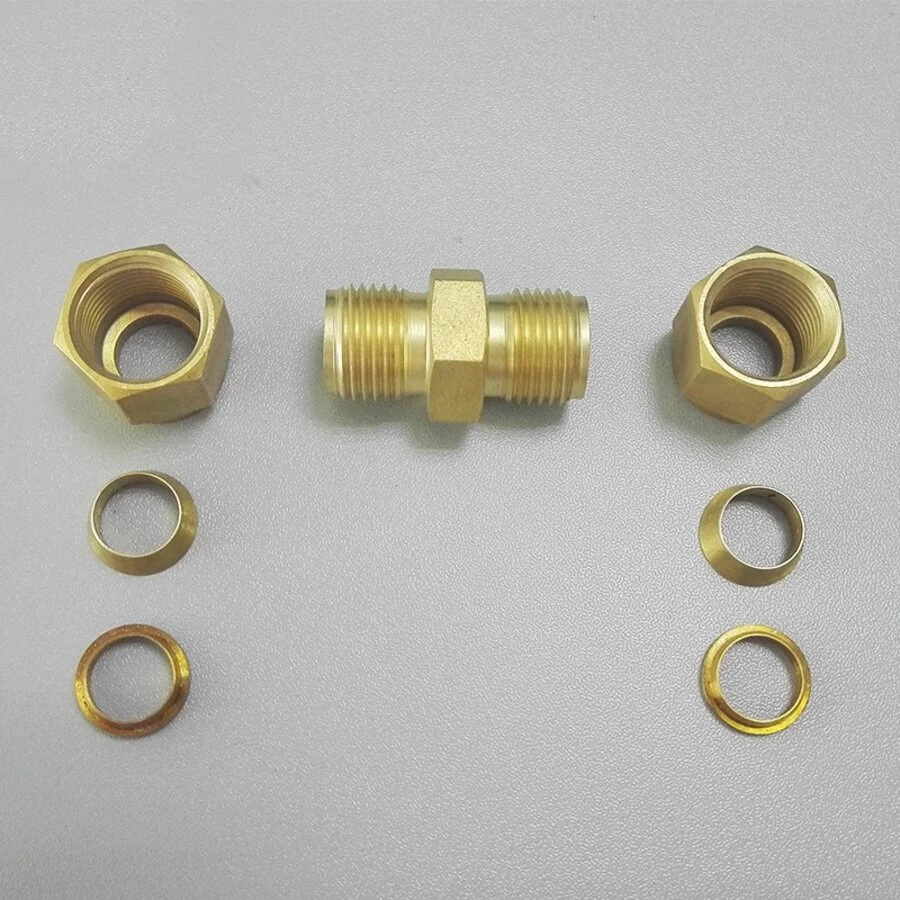

The ferrule type tube fittings( pipe joint) consists of three parts: body, the ferrule and the nut.

What is the sealing principle of the ferrule tube fittings?

The main sealing part of this type tube fitting is the ferrule(cutting rings). As the nut for compression adjustment is tightened continuously, the ferrule ring moves along the axial direction of the inner cone hole of the joint body under the action of the axial force of the nut. , The cone surface of the ring fits the cone surface of the joint body, and the end surface of the rubber ring fits the end surface of the joint body. When all the functional movable nuts are continued to be tightened, the front end surface of the metal ferrule contacts the inner cone surface of the ring, and the metal clamps The sleeve produces a reverse force, and the cutting edge of the ferrule produces different radial shrinkage under the radial action of the reaction force, which gradually eliminates the gap between the ferrule and the tube, and makes the blade contact the surface of the tube, and continue to rotate the nut and ring. The outer cone surface closely fits with the inner cone surface of the joint. Due to the compression, the tapered part of the ring and the pipe are tightly fitted to achieve sealing. At the same time, the cutting edge of the ferrule is also firmly cut into the pipe to ensure a safe and reliable seal. , The tail cone of the ferrule shrinks radially under the action of the force, tightly hugs the connected pipe, while the middle part is slightly arched, so the ferrule has a certain axial elastic deformation, which seals the ferrule and prevents the compression nut from loosening Both have a favorable effect.

Reasons for sealing leakage of ferrule tube fittings:

1. If the steel pipe is not inserted into the end of the metal pipe, the cut of the metal ferrule (cutting rings)cannot be cut, and the secondary sealing ring cannot be formed on the surface of the metal pipe, thus greatly reducing the sealing effect

2. If the nut is not tightened, there will not be enough axial thrust, which may lead to the formation of the main sealing ring and the secondary sealing ring

3. The outer surface of the steel pipe is severely scratched, and the scratched area may not be able to form an effective seal, and there is a hidden danger of leakage.

4. The steel pipe is not round or the diameter tolerance is too large. When the roundness deviation of the steel pipe is large, an effective seal cannot be formed.

5. The steel pipe is too hard. When the steel pipe is too hard, the metal ferrule cannot be cut into the metal pipe, so that an effective secondary sealing ring cannot be formed, and the sealing effect is greatly reduced.

How to effectively solve the leakage of the ferrule tube fittings:

1. Pre-install the axial position of the ferrule on the steel pipe according to the design requirements to ensure that the steel pipe is inserted to the end

2. Tighten the functional nut according to the specified torque. It should not be too tight or too loose. Too loose can not provide enough axial force and can not form an effective seal. Too tight will cause the ferrule to yield and deform and lose its elasticity.

3. Check whether there are scratches on the connecting part of the cold-drawn tube and the ferrule. If there is a scratch, cut off a section of the scratched cold-drawn tube, or replace with a qualified ferrule and reassemble it. The end of the steel pipe should be vertical without burrs

4. The structure requirements of the ferrule type pipe joint must be equipped with high-precision (outer diameter> cold drawn pipe to ensure that the outer diameter of the steel pipe is tightly fitted with the installation ferrule.

5. Low-carbon steel cold drawn pipes need to be normalized, and stainless steel cold drawn pipes need to be fully annealed to ensure that the ferrule effectively cuts into the surface of the steel pipe when the functional nut is tightened.

YC-LOK Jiangsu Yicheng Fluid Equipment Co.,Ltd will serve for you, please contact us if any needs!

What is the sealing principle of the ferrule tube fittings?

The main sealing part of this type tube fitting is the ferrule(cutting rings). As the nut for compression adjustment is tightened continuously, the ferrule ring moves along the axial direction of the inner cone hole of the joint body under the action of the axial force of the nut. , The cone surface of the ring fits the cone surface of the joint body, and the end surface of the rubber ring fits the end surface of the joint body. When all the functional movable nuts are continued to be tightened, the front end surface of the metal ferrule contacts the inner cone surface of the ring, and the metal clamps The sleeve produces a reverse force, and the cutting edge of the ferrule produces different radial shrinkage under the radial action of the reaction force, which gradually eliminates the gap between the ferrule and the tube, and makes the blade contact the surface of the tube, and continue to rotate the nut and ring. The outer cone surface closely fits with the inner cone surface of the joint. Due to the compression, the tapered part of the ring and the pipe are tightly fitted to achieve sealing. At the same time, the cutting edge of the ferrule is also firmly cut into the pipe to ensure a safe and reliable seal. , The tail cone of the ferrule shrinks radially under the action of the force, tightly hugs the connected pipe, while the middle part is slightly arched, so the ferrule has a certain axial elastic deformation, which seals the ferrule and prevents the compression nut from loosening Both have a favorable effect.

Reasons for sealing leakage of ferrule tube fittings:

1. If the steel pipe is not inserted into the end of the metal pipe, the cut of the metal ferrule (cutting rings)cannot be cut, and the secondary sealing ring cannot be formed on the surface of the metal pipe, thus greatly reducing the sealing effect

2. If the nut is not tightened, there will not be enough axial thrust, which may lead to the formation of the main sealing ring and the secondary sealing ring

3. The outer surface of the steel pipe is severely scratched, and the scratched area may not be able to form an effective seal, and there is a hidden danger of leakage.

4. The steel pipe is not round or the diameter tolerance is too large. When the roundness deviation of the steel pipe is large, an effective seal cannot be formed.

5. The steel pipe is too hard. When the steel pipe is too hard, the metal ferrule cannot be cut into the metal pipe, so that an effective secondary sealing ring cannot be formed, and the sealing effect is greatly reduced.

How to effectively solve the leakage of the ferrule tube fittings:

1. Pre-install the axial position of the ferrule on the steel pipe according to the design requirements to ensure that the steel pipe is inserted to the end

2. Tighten the functional nut according to the specified torque. It should not be too tight or too loose. Too loose can not provide enough axial force and can not form an effective seal. Too tight will cause the ferrule to yield and deform and lose its elasticity.

3. Check whether there are scratches on the connecting part of the cold-drawn tube and the ferrule. If there is a scratch, cut off a section of the scratched cold-drawn tube, or replace with a qualified ferrule and reassemble it. The end of the steel pipe should be vertical without burrs

4. The structure requirements of the ferrule type pipe joint must be equipped with high-precision (outer diameter> cold drawn pipe to ensure that the outer diameter of the steel pipe is tightly fitted with the installation ferrule.

5. Low-carbon steel cold drawn pipes need to be normalized, and stainless steel cold drawn pipes need to be fully annealed to ensure that the ferrule effectively cuts into the surface of the steel pipe when the functional nut is tightened.

YC-LOK Jiangsu Yicheng Fluid Equipment Co.,Ltd will serve for you, please contact us if any needs!