Applicable of double ferrule in tube fittings

Luna

2021-09-10 10:42:46

Double ferrule type tube fittings are suitable for: petroleum, chemical, metallurgy, pharmacy, instrumentation, mechanical parts, electric power industry.

The double ferrule type tube fitting is in the form of a conical surface, and the cut-in angle of the ferrule has double sealing. The sealing performance of the double ferrule pipe joint has high pressure bearing capacity and anti-vibration and anti-vibration performance. The pipe can be sealed normally even if it is scratched. The double ferrule pipe joint has corrosion resistance and high pressure vibration. Normal use.

Materials of tube fittings generally include stainless steel, steel, nylon, copper poly, etc.

The difference between double ferrule and single ferrule tube fittings and their advantages and disadvantages :

Double ferrule joints and single ferrule joints are respectively used on the tube. The double ferrule adopts special alloy, which has a large deformation, and can also ensure its tightness and airtightness(sealing to no leak). Its strength is better than other materials.

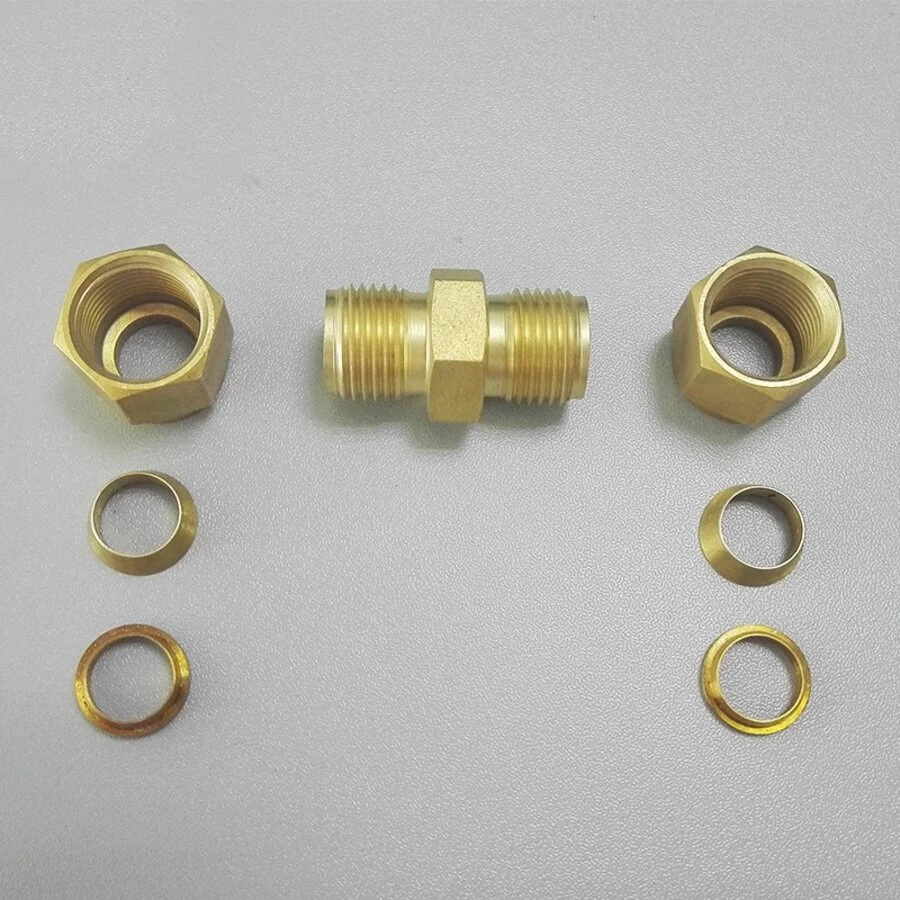

The general tube connection can adopt double or single ferrule joints, and the double snap ring ferrule can be disassembled several times and can ensure the tightness. When the single ferrule type pipe joint is connected with the ordinary tube, because one end has no thread, it needs to be connected with the ordinary pipe, and if there is thread, it needs to be connected with the tube. The large double ferrule can ensure the strength, and the small ferrule can meet the deformation requirements during use. The ferrule joint is mainly composed of a connector body with a 24-degree tapered hole, a ferrule 2 with a sharp inner blade, and a compression nut 3 with a compression effect. When the nut 3 is tightened, the ferrule 2 is pushed into the taper hole of 24 degrees and deformed accordingly, so that the ferrule and the conical surface of the joint body form a spherical touch seal. The inner cutting edge of the ferrule is embedded in the outer wall of the steel pipe 4, and a circular groove is pressed on the outer wall, and then it has the effect of a firm seal. The best choice for steel pipe is stress-relieving annealing 20# fine drawn pipe, which will help the inner blade of the ferrule joint to be embedded in the outer surface of the steel pipe to achieve a firm sealing effect.

The double ferrule type tube fitting is in the form of a conical surface, and the cut-in angle of the ferrule has double sealing. The sealing performance of the double ferrule pipe joint has high pressure bearing capacity and anti-vibration and anti-vibration performance. The pipe can be sealed normally even if it is scratched. The double ferrule pipe joint has corrosion resistance and high pressure vibration. Normal use.

Materials of tube fittings generally include stainless steel, steel, nylon, copper poly, etc.

The difference between double ferrule and single ferrule tube fittings and their advantages and disadvantages :

Double ferrule joints and single ferrule joints are respectively used on the tube. The double ferrule adopts special alloy, which has a large deformation, and can also ensure its tightness and airtightness(sealing to no leak). Its strength is better than other materials.

The general tube connection can adopt double or single ferrule joints, and the double snap ring ferrule can be disassembled several times and can ensure the tightness. When the single ferrule type pipe joint is connected with the ordinary tube, because one end has no thread, it needs to be connected with the ordinary pipe, and if there is thread, it needs to be connected with the tube. The large double ferrule can ensure the strength, and the small ferrule can meet the deformation requirements during use. The ferrule joint is mainly composed of a connector body with a 24-degree tapered hole, a ferrule 2 with a sharp inner blade, and a compression nut 3 with a compression effect. When the nut 3 is tightened, the ferrule 2 is pushed into the taper hole of 24 degrees and deformed accordingly, so that the ferrule and the conical surface of the joint body form a spherical touch seal. The inner cutting edge of the ferrule is embedded in the outer wall of the steel pipe 4, and a circular groove is pressed on the outer wall, and then it has the effect of a firm seal. The best choice for steel pipe is stress-relieving annealing 20# fine drawn pipe, which will help the inner blade of the ferrule joint to be embedded in the outer surface of the steel pipe to achieve a firm sealing effect.