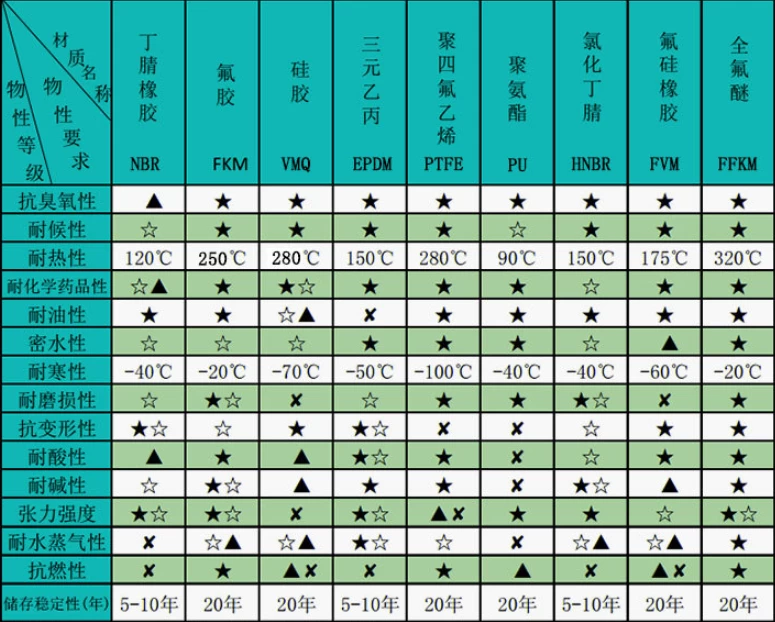

The characteristics of the rubber ring and the degree of high temperature resistance of different ma

First, the characteristics of the rubber ring

1. The rubber material has excellent heat resistance, cold resistance, ozone resistance and atmospheric aging resistance. It has good insulating properties. But the tensile strength is worse than ordinary rubber and not oil resistant. Suitable for household appliances such as electric water heaters, electric irons, microwave ovens, etc. It is also suitable for various articles that come into contact with the human body, such as kettles, water dispensers, etc.

2. It is not recommended to be used in most concentrated solvents, oil products, concentrated acids and sodium hydroxide. The general operating temperature range is -55~250 ℃. Its high temperature resistance is better than that of silicone rubber, and it has excellent weather resistance, ozone resistance and chemical resistance, but its cold resistance is poor.

3. It is resistant to most oils and solvents, especially acids, aliphatic hydrocarbons, aromatic hydrocarbons and animal and vegetable oils. Suitable for sealing requirements of diesel engines, fuel systems and chemical plants. It is not recommended to be used in ketones, low molecular weight esters and mixtures containing nitrous.

4. Its performance has the advantages of both fluorine rubber and silicone rubber, and it has good oil resistance, solvent resistance, fuel oil resistance and high and low temperature resistance. It can resist the corrosion of oxygen-containing compounds, solvents containing aromatic hydrocarbons and solvents containing chlorine. Generally used in aviation, aerospace and military purposes. Exposure to ketones and brake fluid is not recommended.

Second, How much high temperature can rubber rings of different materials withstand?

1. Nitrile rubber

Up to 130 degrees high temperature working temperature range (-40-120°C).

2. Fluorine rubber (FPM)

Strong high temperature resistance, up to 280 degrees high temperature, good anti-aging and oxidation resistance, very low gas permeability, working temperature range (-20-280 ° C).

3. Ethylene Propylene Diene Monomer (EPDM)

The temperature range is -50 ~ 150 ° C, with the characteristics of hot water resistance, steam resistance, aging resistance and chemical resistance

4. Silica gel (SI)

Third. What should be paid attention to when installing the rubber ring

1. Do not install in the wrong direction and damage the lips. If there is a scratch of more than 50μm on the lip, it may cause obvious oil leakage.

2. Prevent forced installation. It cannot be knocked in with a hammer, but a special tool should be used to press the sealing ring into the seat hole first, and then use a simple circle to protect the lip through the spline. Before installation,

Apply some lubricating oil to the lips to facilitate installation and prevent initial operation, and pay attention to cleaning.

3. Prevent overdue use. The service life of the dynamic sealing rubber sealing ring is generally 3000~5000h, and the sealing ring should be replaced in time.

4. The size of the replacement sealing ring should be consistent. Strictly follow the requirements of the instructions and choose the same size sealing ring, otherwise the compression degree and other requirements cannot be guaranteed.

5. Avoid using old sealing rings. When using a new sealing ring, carefully check its surface quality, make sure there are no small holes, protrusions, cracks and grooves, etc., and have enough elasticity before using it.

use.

6. During installation, all parts of the opened hydraulic system should be strictly cleaned first, and special tools should be used to prevent fingers from being scratched by sharp metal edges.

7. When replacing the sealing ring, strictly check the sealing ring groove, dirt, and polish the bottom of the groove.

8. In order to prevent oil leakage due to damage, it must be operated according to the regulations. At the same time, the machine cannot be overloaded for a long time or placed in a relatively harsh environment.