Installation method of ferrule joint

Installation method of ferrule joint

1. Saw a seamless steel pipe of appropriate length to remove burrs at the ports. The end face of the pipe shall be perpendicular to the axis, and the angular tolerance shall not be greater than 0.5 °. If the pipe needs to be bent, the length of the straight line from the end of the pipe to the bent part must not be less than three times the length of the nut.

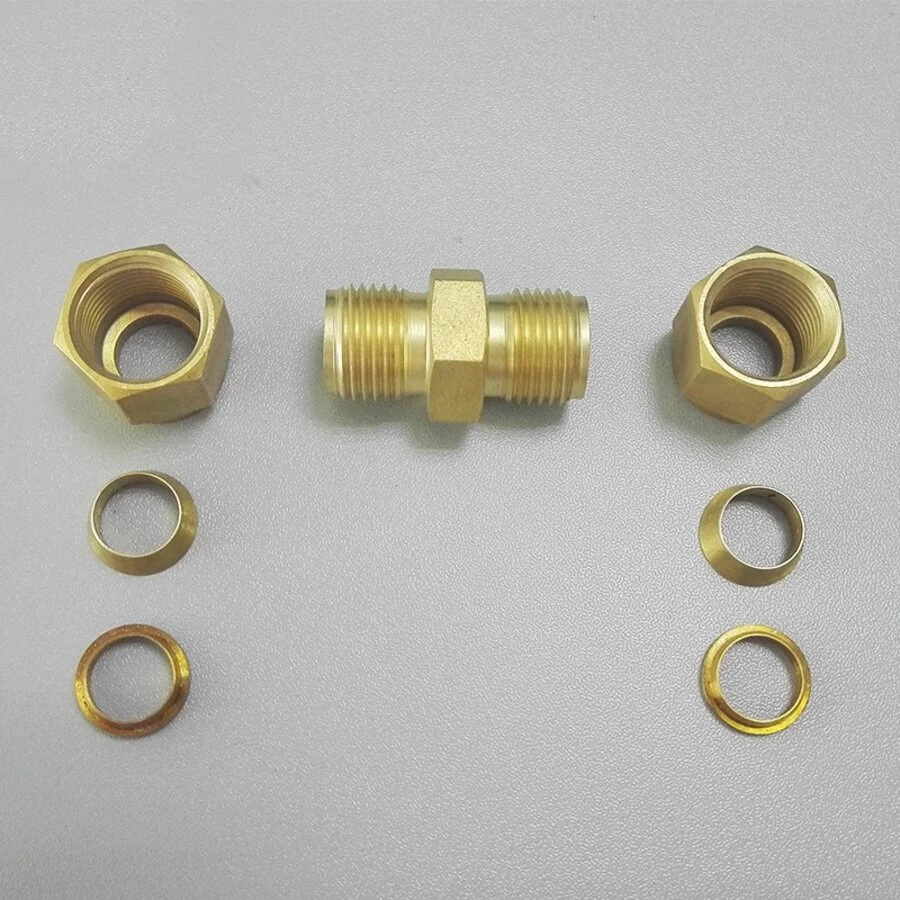

2. Put the nut and ferrule on the seamless steel pipe. Pay attention to the direction of the nut and ferrule, do not install it upside down.

3. Lubricate the threads and ferrules of the pre-assembled joint body, insert the pipe into the joint body (the pipe must be inserted to the end), and tighten the nut by hand.

4. Tighten the nut until the ferrule catches the pipe. This turning point can be felt by increasing the tightening torque (pressure point).

5. After reaching the pressure point, tighten the compression nut 1/2 turn.

6. Remove the pre-assembled connector body and check the insert of the edge of the ferrule. The visible protruding band must fill the space on the end face of the ferrule. The ferrule can be rotated slightly, but it cannot be moved axially.

7. For final installation, lubricate the threads of the joint body in the actual installation, and tighten the nuts with it until the perceived tightening force increases. Then tighten 1/2 turn to complete the installation.

Installation instructions for ferrule joints

When installing the ferrule joint, the inside and outside of the pipe joint interface connected to the ferrule joint must be cleaned. The pipe joint must be polished and flat, and the surface must be free of burrs and uneven surfaces. In addition, there should be no bending phenomenon in the embedding part of the pipe joint and the ferrule joint, otherwise the joint between the ferrule joint and the steel pipe will leak. The steel pipes at the two ends of the connected ferrule joint are preferably made of a uniform material, which can effectively prevent leakage.

After the steel pipe is inserted into the ferrule joint body, the strength of the tightening of the ferrule should not be too large. The ferrule should be tightened to the thread tail or 2/3 step by step. The ferrule can be tightened with a wrench.