Types of hydraulic tube fittings

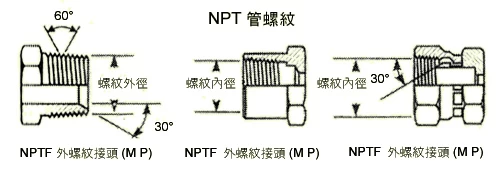

1, NPTF conical threaded joint

Note: This is a dry-sealed thread; it is a domestic tapered pipe thread used to transport fuel. It can be used for both external and internal thread end joints. NPTF external threads can be mated with NPTF, NPSF or NPSM internal threads. NPTF pipe joints are similar to BSPT pipe joints but not interchangeable. The pitch of most sizes of threads is different and the profile angle is 60 °, while the profile angle of BSPT threads is 55 °.

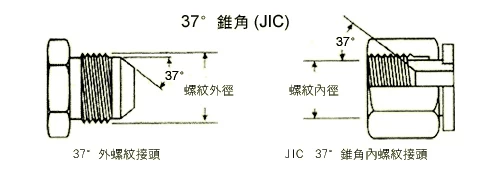

2.JIC37 ° tapered female connector

Note: The 37 ° cone angle (JIC) Association of Automotive Engineers (SAE) stipulates that 37 ° cone angle or cone seat can be used for high-pressure hydraulic pipelines. This type of fitting is often referred to as a JIC fitting. The JIC external thread can only be matched with the JIC internal thread. The JIC external thread is a straight thread and has a 37 ° conical seating surface. The JIC internal thread is also a straight thread and has a 37 ° conical seating surface. The seal is formed at the 37 ° cone seat surface. Some sizes of threads are the same as SAE 45 ° cone angle threads. The cone angle should be carefully measured to distinguish them.

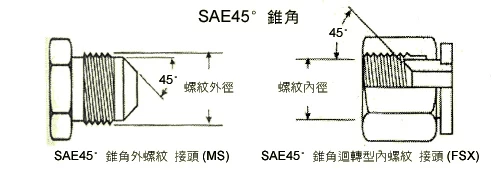

3, SAE 45 ° cone angle external thread joint

Explanation: SAE (45 ° cone angle) This is the term used for pipe joints with a 45 ° cone angle or cone seat. This joint is usually used for soft copper pipes because the material is easy to machine to 45 °. This fitting is suitable for low pressure applications-for example for fuel and refrigeration lines. SAE 45 ° taper external threads can only be used with SAE 45 ° taper internal threads. The SAE male thread is straight and has a 45 ° cone seating surface. The SAE internal thread is also straight and has a 45 ° cone seating surface. Its seal is formed at the 45 ° cone seat surface. Some thread sizes are the same as SEA 37 ° taper threads. The taper angle should be carefully measured for zoning.

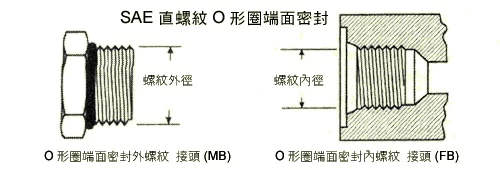

4. O-ring end seal male screw joint

Note: The O-ring end seal external thread can only cooperate with the O-ring end seal internal thread. The external thread is a straight thread with an O-ring; the internal thread is a straight thread with a sealing end. The external thread is sealed at the O-ring The internal thread is sealed at the sealing end face.

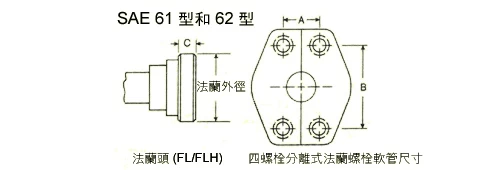

5, O-shaped flange-SAE J518

Description: SAE J518SAE Type 61 and Type 62 four-bolt split flanges are commonly used worldwide to connect pumps and motors.

There are three exceptions here;

1. Multiplying factor -10, not SAE standard size, but it is widely used outside North America

2. Caterpillar flange has a thicker flange head (size "C" in the table) and its outer diameter is as large as the outer diameter of SAE 62 flange.

3. Poclain flange, which is fundamentally different from SAE flange.

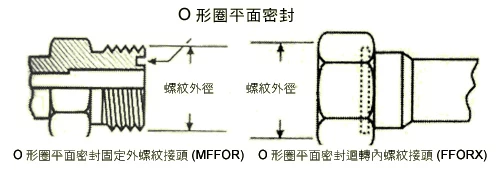

6. O-ring flat seal fixed external thread joint

Note: A seal is formed when the O-ring on the male screw joint comes in contact with the plane on the female screw joint. In the hydraulic system, an elastomer seal can be used to control the leakage, and this type of leakage can be used when the leakage prevention function is extremely important. Pipe joint

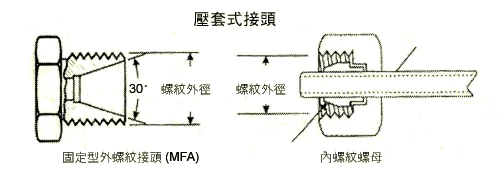

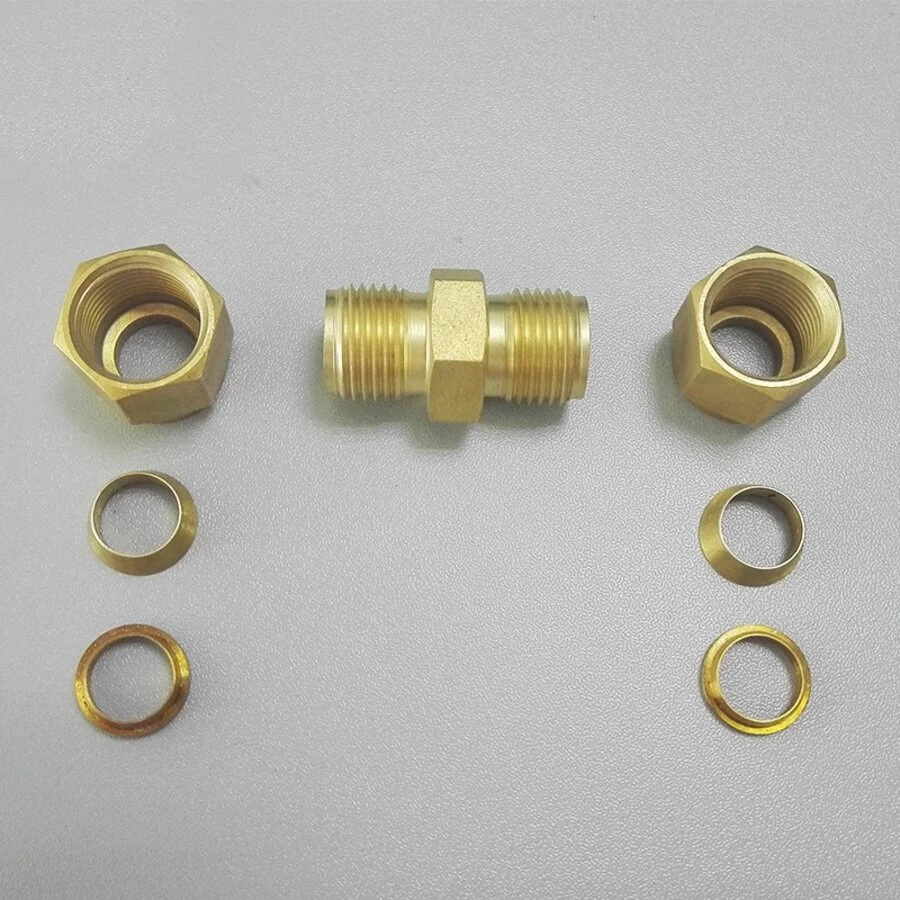

7, compression sleeve type pipe joint

Note: The fixed sleeve type external thread joint can only be matched with the compressed sleeve type internal thread nut and the pressure sleeve. The male connector is a straight thread with a 24 ° cone. The female thread head is straight and has a compression sleeve as a tight cover. The seal is formed between the compression sleeve and the 24 ° cone seat of the external thread joint, and between the compression sleeve and the inner tube of the internal thread joint.