Difference between double ferrule compression connector and single ferrule connector

Difference between double ferrule compression connector and single ferrule connector

The main differences between are their structure, sealing performance, scope of application, and installation characteristics.

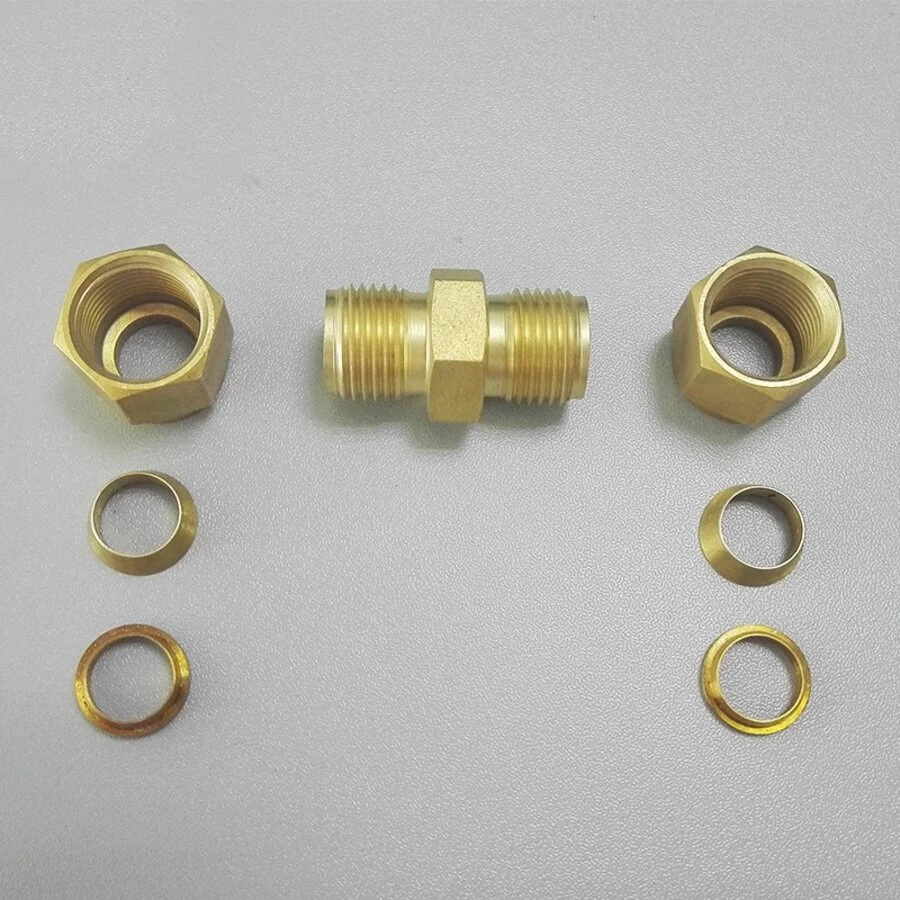

Structural difference: The double ferrule compression connector consists of two cutting rings type connectors, while the single ferrule connector only has one cutting ring type connector. This structural difference makes the double ferrule type perform better in terms of connection reliability and pressure resistance.

Sealing performance: Due to its special double cutting rings design, it has higher sealing performance, can withstand higher pressure and vibration, and can maintain normal operation even under high-pressure vibration. In contrast, the sealing performance of single ferrule joints is relatively low, but they are easy to install and can adapt to certain bending and expansion, making pipeline connections more flexible.

Scope of application: Double ferrule joints are suitable for industries such as crude oil, chemical, metallurgical, pharmaceutical, instrumentation, mechanical equipment manufacturing, and power due to their high sealing and pressure resistance. Due to its flexibility and simplicity of installation, single ferrule type connectors are also widely used in various occasions that require pipeline connections.

Installation characteristics: The installation of double ferrule compression type fittings requires ensuring that the two cutting rings can evenly and moderately cut into the pipe wall, forming an effective seal. The installation of a single ferrule type connector is relatively simple, but due to only one end being clamped, its sealing performance and pressure resistance are relatively low.

In summary, the double ferrule joint is superior to the single ferrule joint in terms of sealing performance, pressure resistance, and applicability, while the single ferrule joint has advantages in installation simplicity and certain bending and expansion capabilities. The choice of which type of connector to use depends on specific application requirements and environmental conditions. The characteristics of connectors make it more convenient for everyone to choose.