Differences between Butt Welding and Socket Welding

Analysis of Welding Techniques - Differences between Butt Welding and Socket Welding

In the current industrial manufacturing and construction industries, welding technology, as an important means of connecting metal materials, has a wide range of applications. Among various welding methods, butt welding and socket welding have become the focus of attention for many manufacturers and buyers due to their respective characteristics and applicable scenarios.

Welding techniques are mainly divided into the following types: arc welding, gas shielded welding, laser welding, resistance welding, butt welding, and socket welding. Each welding method has its unique application scenarios and advantages.

Butt welding is a technique that connects two metal end faces by pressing or heating them together. This method is suitable for docking connections of pipes, plates, etc., with high welding strength and suitable for high-pressure and high-temperature working conditions. Butt welded joints have a smooth appearance, are easy to inspect and maintain, and are one of the commonly used welding methods in industrial pipeline systems.

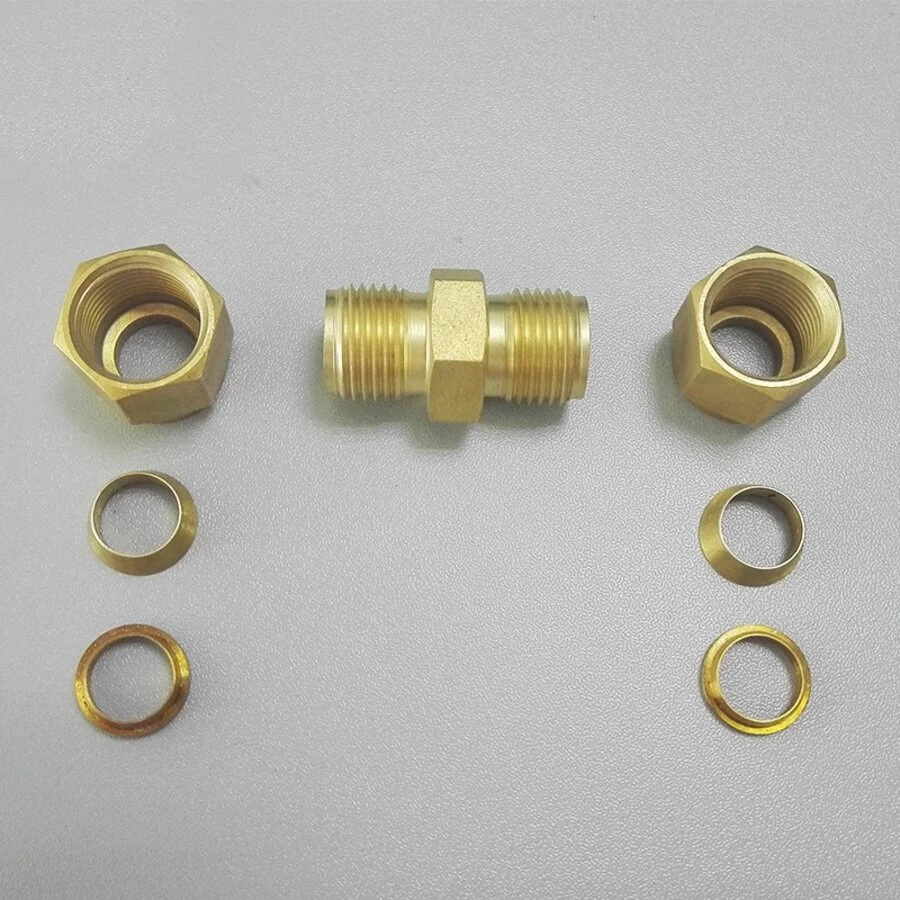

Socket welding is the process of inserting a metal pipe into the socket of another metal pipe or fitting and fixing it by welding. This welding method is easy to operate and suitable for connecting small-diameter pipelines or low-pressure systems. Socket welding joints have good sealing properties and are suitable for situations that require frequent disassembly or maintenance.

In the field of foreign trade, choosing the appropriate welding method is crucial for the quality of products and the reliability of engineering. Butt welding is commonly used in industries such as petroleum, natural gas, and chemical due to its high strength and pressure resistance; And socket welding is widely used in building water supply and drainage systems and HVAC engineering due to its convenient construction and low cost.

With the continuous improvement of global industrial manufacturing standards, the selection and application of welding technology have become important considerations in foreign trade cooperation. Understanding the difference between butt welding and socket welding can help buyers and manufacturers make more accurate technical matches in practical applications, improving overall engineering quality and safety.

If you need to learn more about welding technology details or product information, please feel free to contact our professional team for support.YC-LOK department! sales01@yc-lok.com