About how to use stainless steel tube fittings

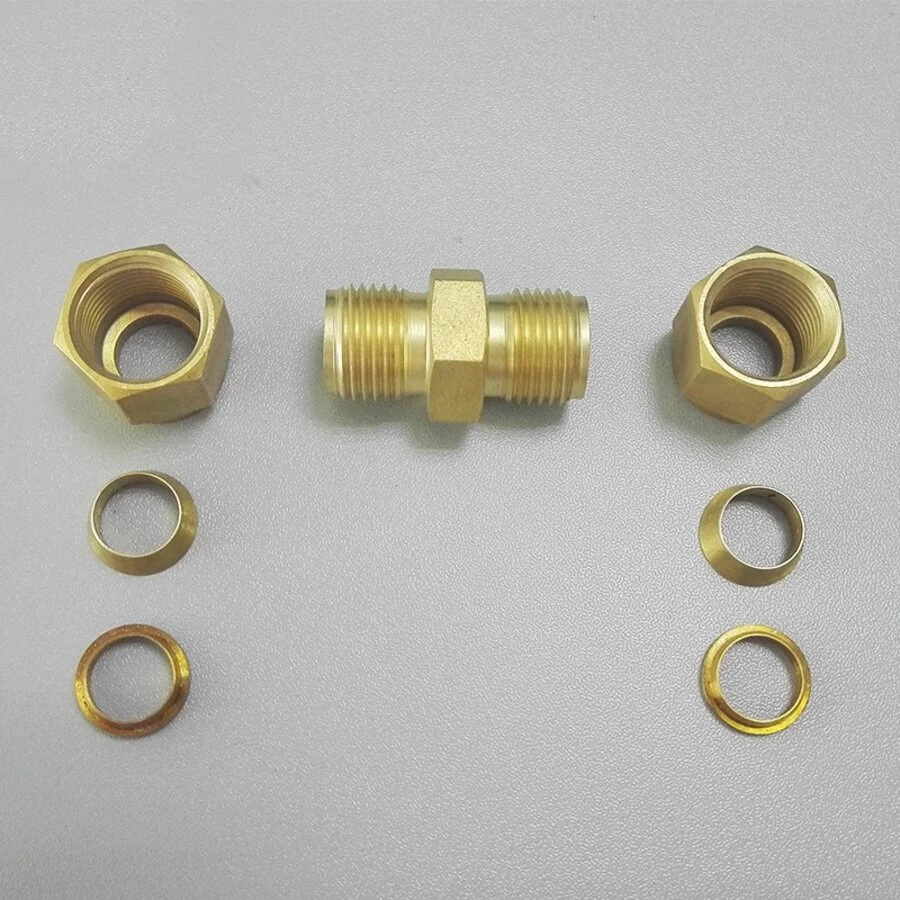

In industrial applications, we often use stainless steel pipe joints. However, for nonprofessional people, there will be some unfamiliar places when choosing or applying this kind of products. Next, let's learn the problems we should pay attention to when choosing and using stainless steel fast joints.

JIANGSU Yicheng Fluid Equipment Co., Ltd

1. About the Correct Selection of Stainless Steel Pipe Joints

(1) Determine the joint from the type of fluid and temperature. The types and temperatures of fluids have a great influence on the quality of the joints, so they should be selected according to local conditions. If the stainless steel quick joint is air, steel joint, brass or stainless steel joint can be selected if water.

(2) Choose suitable joint according to the pressure of liquid. Fluid pressure is also the key to the selection of stainless steel fast joints. The pressure resistance of joints with different structures is different.

2. About Correct Use of Stainless Steel Pipe Joints

(1) conditions. The humidity, dust and corrosivity of the joint used in the condition have a great influence on the effect of the joint. Before use, we should select suitable application conditions according to the characteristics of stainless steel fast joint, such as type, body material, sealing material and so on.

(2)installation. The size of fluid flow determines the type of joint, and pipes of corresponding shape and size should also be equipped.

(3)for use. It should not exceed the maximum pressure limit. Temperature, humidity and corrosivity should be controlled within the scope of use. Do not deliberately damage stainless steel joints, find someone to repair the defective joints, and do not disassemble them at will.

3.Features of stainless steel fast joints:

(1) Time-saving and labor-saving: When the oil pipeline is disconnected and connected through the fast joint, the action is simple, and the time and manpower are saved.

(2) Oil saving: When breaking the oil line, the single valve on the quick joint can close the oil line, and the oil will not flow out, so as to avoid oil pressure loss.

(3) Environmental protection: When the quick joint is broken and connected, oil will not spill and protect the environment.

(4) Equipment design is unique and convenient for transportation: large-scale equipment or hydraulic tools need to be easy to carry, which are transported after splitting with fast connectors, and then assembled and used after arriving at the destination.

(5) Economy: All these advantages create economic value for customers.

Pipe joint manufacturer reminds you of the precautions in use:

1. Do not use for fluids other than fluids.

2. Do not exceed the maximum pressure limit when using.

3. Do not use outside the use temperature range to prevent abrasion or leakage of sealing materials.

4. Do not strike, bend, stretch or cause damage artificially.

5. Do not mix metal powder or sand dust and other places to use, to prevent bad work or leakage.

6. Installation of threads should not exceed the maximum tightening torque to prevent damage.

7. Do not use cracked hose to prevent leakage or fall off.

8. The durability of machines with vibration and impact will be reduced.

9. The use of fluids must be clean fluids filtered through filters.

10. Do not disassemble the quick connector.