How to check the wear of the sealing surface of the stainless steel joint

Luna

2022-07-14 13:46:43

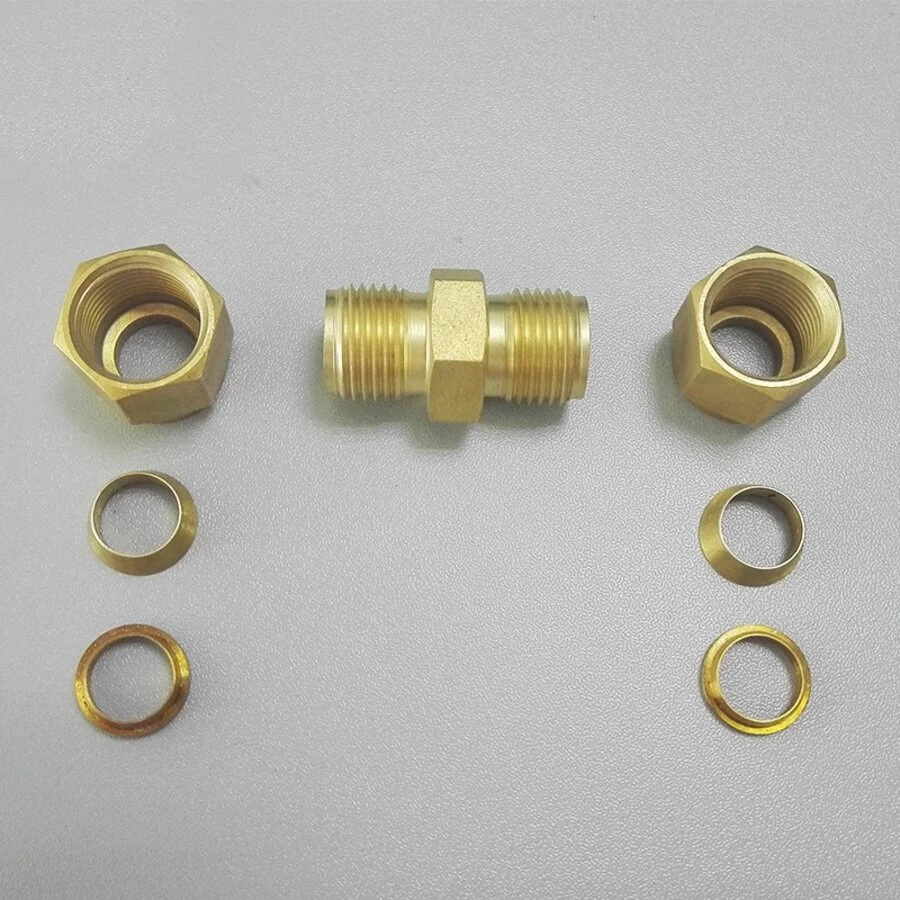

Check the wear condition and thickness change of the sealing surface of the stainless steel soft joint (normal wear is generally 5-10 mm); observe the friction track of the sealing surface to see if there are three-point intermittent or scratches. If so, it should be replaced immediately. Usually in the assembly process, the leakage of hydraulic stainless steel soft joint is caused by irregular operation, insufficient concentricity of the rotor part of the stainless steel soft joint, or low degree of fitting and connection and large vibration.

The sealing surface of the stainless steel soft joint is damaged due to the entry of small particles such as dust or dirt into the hydraulic stainless steel soft joint; in theory, the stainless steel soft joint is not easy to rust. We need to check the size and degree of the corresponding shaft head and stainless steel soft joint parts, and properly adjust the connection with the stainless steel soft joint rotor parts. If the failure still occurs, it is necessary to determine whether it is necessary to repair the shaft head part of the equipment. Of course, if it is a stainless steel soft joint, you need to replace the stainless steel soft joint.

The secret of stainless steel soft joints is that some metal chromium is added to carbon steel, and the composition is not low. At about 12%, chromium and co2 will be generated after he contacts the gas, which is reflected in the formation of a high-density passivation film on the surface of carbon steel, so that stainless steel pipe fittings can be maintained reasonably and continuously. Moreover, this passive film is very thin, and the gloss of the surface of the stainless steel soft joint can be seen, so that the stainless steel soft joint has some very distinctive surface characteristics. However, in order to ensure that this protective film is not damaged, once it is damaged, the exposed steel will react directly with CO2, which will affect the passivation film in the process and resume work.

The sealing surface of the stainless steel soft joint is damaged due to the entry of small particles such as dust or dirt into the hydraulic stainless steel soft joint; in theory, the stainless steel soft joint is not easy to rust. We need to check the size and degree of the corresponding shaft head and stainless steel soft joint parts, and properly adjust the connection with the stainless steel soft joint rotor parts. If the failure still occurs, it is necessary to determine whether it is necessary to repair the shaft head part of the equipment. Of course, if it is a stainless steel soft joint, you need to replace the stainless steel soft joint.

The secret of stainless steel soft joints is that some metal chromium is added to carbon steel, and the composition is not low. At about 12%, chromium and co2 will be generated after he contacts the gas, which is reflected in the formation of a high-density passivation film on the surface of carbon steel, so that stainless steel pipe fittings can be maintained reasonably and continuously. Moreover, this passive film is very thin, and the gloss of the surface of the stainless steel soft joint can be seen, so that the stainless steel soft joint has some very distinctive surface characteristics. However, in order to ensure that this protective film is not damaged, once it is damaged, the exposed steel will react directly with CO2, which will affect the passivation film in the process and resume work.