Introduction to the manufacturer of ferrule pipe joint

Jason

2020-06-30 15:11:56

Introduction to the manufacturer of ferrule pipe joint

1.Types of ferrule tube fittings

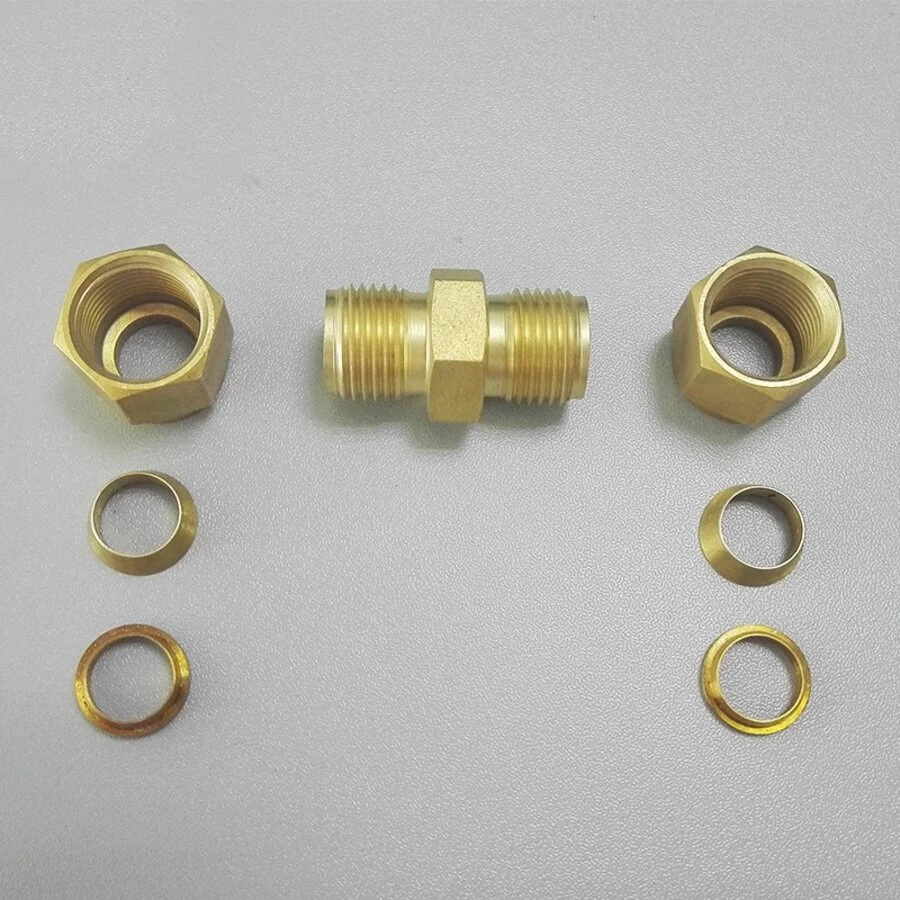

1.1、 Single ferrule type ferrule connector(union tube fittings)

The single ferrule type ferrule joint consists of three parts: joint body, ferrule and nut. When the ferrule and nut sleeve are inserted into the joint body on the steel pipe, when the nut is tightened, the outer front end of the ferrule fits with the conical surface of the joint body, and the inner edge evenly bites into the seamless steel pipe to form an effective seal.

1.2、 Double ferrule connector(union tube fittings)

Structural features: when assembling the pipe joint with advanced geometric design features (as shown in the left figure), the front ferrule is pushed into the joint body and the ferrule to form the main seal, and then the ferrule acts as a hinge inward to form a strong grip on the ferrule. The geometry of the back ferrule contributes to the advanced engineering hinge clamp action, which transforms axial motion into radial extrusion on the ferrule.

2. Advantages of mechanical clamping design of double ferrule:

The double ferrule separates the sealing function from the clamping function, and each ferrule is optimized according to its corresponding function. The front ferrule is used to form the seal:

■ the seal between the joint body and the outer diameter of the ferrule. When rotating the nut, the rear ferrule will:

■ push forward the front ferrule along the axial direction

■ apply an effective ferrule along the radial direction to grasp.

3. Advantages of using the product:

■ excellent gas seal and ferrule grip

■ easy to install correctly

■ excellent vibration fatigue resistance and ferrule support

4. Assembly of double ferrule joint and stainless steel pipe

4.1 ensure that all parts are clean and free from contamination during the whole assembly process.

4.2. Pipe treatment:

4.2.1 the part of the pipe surface inserted into the ferrule joint shall be smooth and intact to avoid scratch and other defects.

4.2.2 the end face of the pipe shall be perpendicular to the axis of the pipe, and the pipe orifice shall be free of burr.

4.2.3 if the pipe is to be bent, a certain length shall be reserved at the end of the pipe, as shown in Fig. 3 L value. The recommended value given by the manufacturer of the joint shall be followed. Generally, the length of l shall not be less than 3 times the length of the nut, otherwise the insertion and sealing of the pipe will be affected.

1.Types of ferrule tube fittings

1.1、 Single ferrule type ferrule connector(union tube fittings)

The single ferrule type ferrule joint consists of three parts: joint body, ferrule and nut. When the ferrule and nut sleeve are inserted into the joint body on the steel pipe, when the nut is tightened, the outer front end of the ferrule fits with the conical surface of the joint body, and the inner edge evenly bites into the seamless steel pipe to form an effective seal.

1.2、 Double ferrule connector(union tube fittings)

Structural features: when assembling the pipe joint with advanced geometric design features (as shown in the left figure), the front ferrule is pushed into the joint body and the ferrule to form the main seal, and then the ferrule acts as a hinge inward to form a strong grip on the ferrule. The geometry of the back ferrule contributes to the advanced engineering hinge clamp action, which transforms axial motion into radial extrusion on the ferrule.

2. Advantages of mechanical clamping design of double ferrule:

The double ferrule separates the sealing function from the clamping function, and each ferrule is optimized according to its corresponding function. The front ferrule is used to form the seal:

■ the seal between the joint body and the outer diameter of the ferrule. When rotating the nut, the rear ferrule will:

■ push forward the front ferrule along the axial direction

■ apply an effective ferrule along the radial direction to grasp.

3. Advantages of using the product:

■ excellent gas seal and ferrule grip

■ easy to install correctly

■ excellent vibration fatigue resistance and ferrule support

4. Assembly of double ferrule joint and stainless steel pipe

4.1 ensure that all parts are clean and free from contamination during the whole assembly process.

4.2. Pipe treatment:

4.2.1 the part of the pipe surface inserted into the ferrule joint shall be smooth and intact to avoid scratch and other defects.

4.2.2 the end face of the pipe shall be perpendicular to the axis of the pipe, and the pipe orifice shall be free of burr.

4.2.3 if the pipe is to be bent, a certain length shall be reserved at the end of the pipe, as shown in Fig. 3 L value. The recommended value given by the manufacturer of the joint shall be followed. Generally, the length of l shall not be less than 3 times the length of the nut, otherwise the insertion and sealing of the pipe will be affected.