YC-LOK Hot Sale - Metric Thread tube fittings

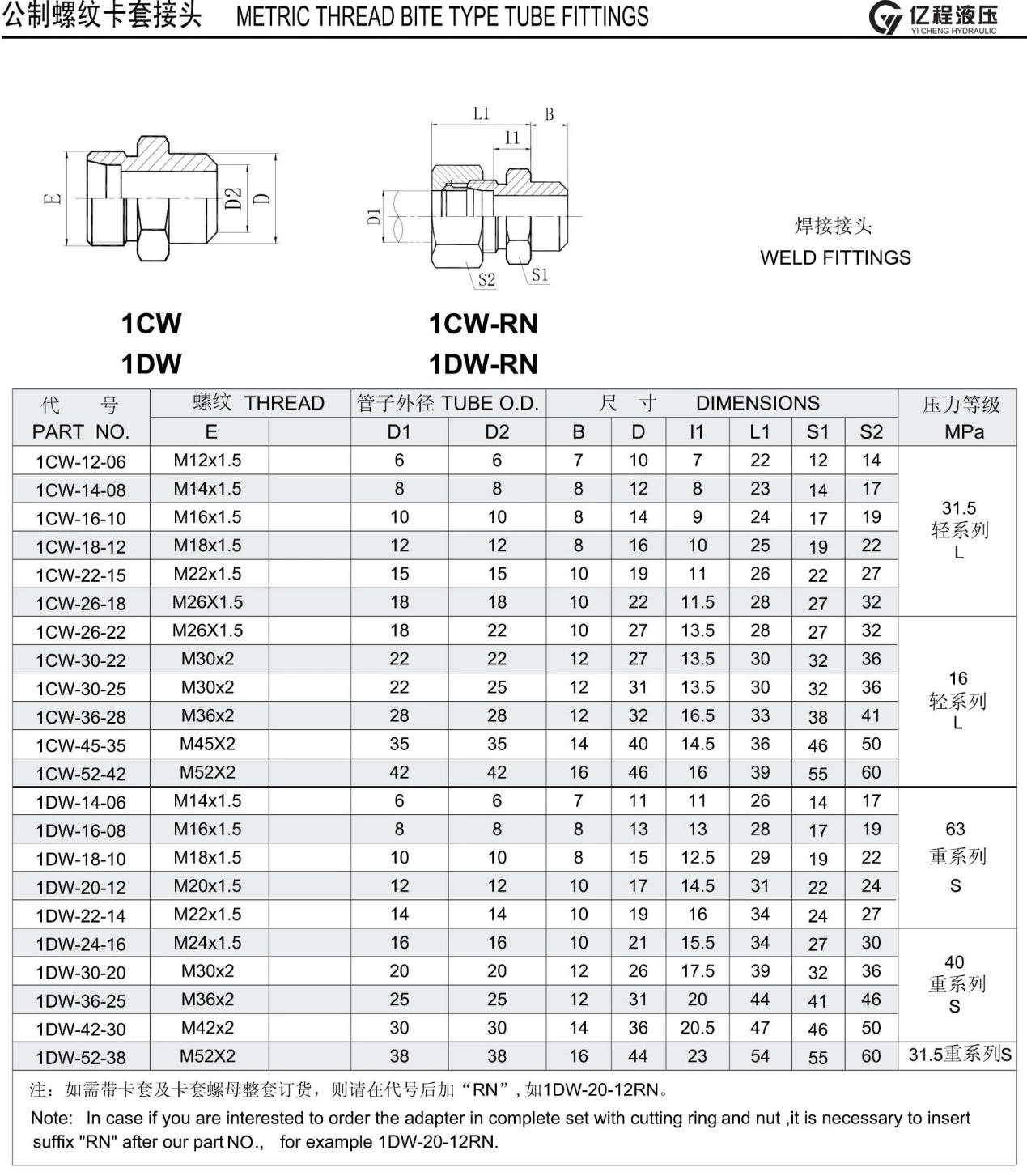

Metric Thread Bite Type Weld Fitting 1CW/1DW

DIN standard connector internal thread main branch three - way clip sleeve connector, in the case of external thread hydraulic equipment needs the main branch oil circuit and main branch oil circuit need to be used when the diameter.

No leakage technology: Ensure no leakage sealing technology, even using low viscosity media, such as water or gas, will not occur leakage, therefore, the hydraulic system will not appear leakage of joints.

High installation efficiency: Compared with welding, the installation efficiency is higher and more convenient.

Reusable: The connection mode can be disassembled for many times without wearing the inner cone of the joint.

Appearance: Galvanized joint surface treatment, beautiful and generous.Compared with the international joint, the rust may be greatly reduced, making the hydraulic system more artistry.

Quality assurance: All components and installation processes have been verified and customers do not need to test separately.It also has shock resistance and durability, which can be used under high pressure for years without re-tightening.

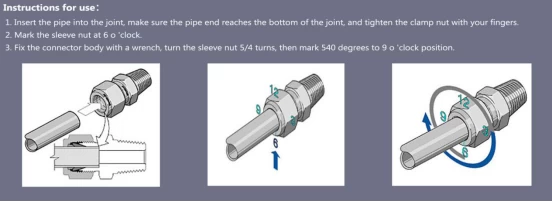

Tips(In the process of tightening 5/4 turn of the clamp nut, the following designed actions are completed once inside the connector)

1. Through screw mechanical propulsion, the forward movement of the sleeve nut pushes the forward movement of the back sleeve, and the forward movement of the front sleeve pushes the back sleeve.

2. Extrude the clamp sleeve inward on the conical surface of the connector body.

3. The sleeve eliminates the tolerance between its inner diameter and the pipe.

4. With the advance of the sleeve, the sleeve moves forward and inward, and the rear end lifts to form a seal with the taper surface of the joint.

5. As the pipe gradually deforms, the tapered surface of the joint and the contact surface of the sleeve increase, and the greater resistance forces the back sleeve to move inward, thus forming a second solid support on the pipe.6. After tightening the sleeve nut by 5/4 turn, it advances by 1/16 (inch) and the connector completes the sealing and holding of the pipe.