hydraulic pipeline system connection

Luna

2021-09-24 15:34:53

Jiangsu Yicheng fluid equipment CO.,Ltd

Each hydraulic, pneumatic or lubrication system has some installation requirements for hydraulic joints and hard pipe pipelines, and the correct installation and assembly of pipelines can help to improve the efficiency of the whole system, prevent leakage, and beautify the overall appearance.

After determining the hard pipe size and hydraulic joint type, the following points shall be considered in the system design:

1、 Can the connection succeed

2、 Is the pipe routing correct

3、 Is there sufficient pipeline support

4、 Are all installation tools available

Several principles for steel pipe layout:

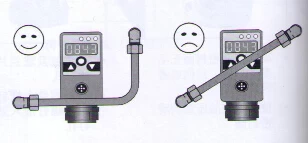

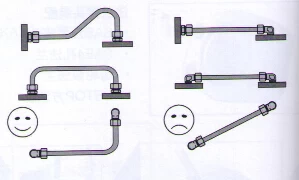

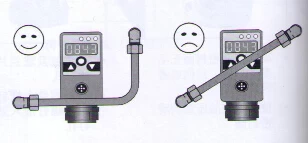

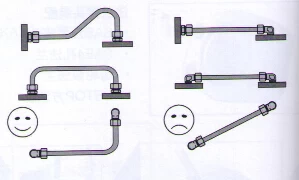

To prevent leakage - when the pipeline is connected straight, it is recommended to bend the steel pipe to prevent leakage caused by stress concentration at the connection of hydraulic joint. In long-distance connection, it is recommended to use hydraulic hose to compensate for the influence of thermal expansion and cold contraction of pipeline system.

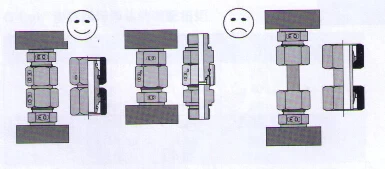

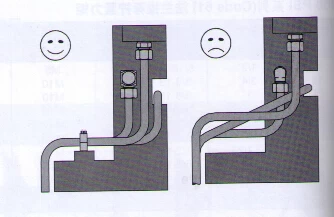

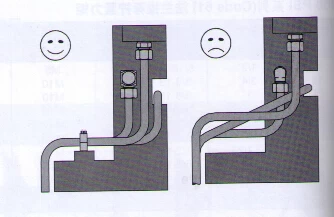

Simple and beautiful - when the system is connected with multiple pipelines, it shall be kept parallel as far as possible and properly fixed with pipe clamps. In addition, during pipe laying, those parts requiring maintenance shall be avoided for routine maintenance and repair.

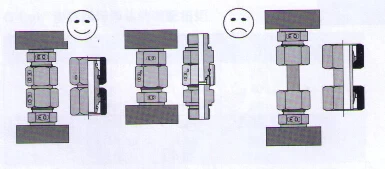

Safe and practical - short pipe connection is easy to cause fatigue damage. It is recommended to use transition joint instead of short pipe connection. When using the pipe clamp, it needs to be fixed, and the appropriate pipe clamp arrangement can properly eliminate the impact of vibration on the joint connection.

Each hydraulic, pneumatic or lubrication system has some installation requirements for hydraulic joints and hard pipe pipelines, and the correct installation and assembly of pipelines can help to improve the efficiency of the whole system, prevent leakage, and beautify the overall appearance.

After determining the hard pipe size and hydraulic joint type, the following points shall be considered in the system design:

1、 Can the connection succeed

2、 Is the pipe routing correct

3、 Is there sufficient pipeline support

4、 Are all installation tools available

Several principles for steel pipe layout:

To prevent leakage - when the pipeline is connected straight, it is recommended to bend the steel pipe to prevent leakage caused by stress concentration at the connection of hydraulic joint. In long-distance connection, it is recommended to use hydraulic hose to compensate for the influence of thermal expansion and cold contraction of pipeline system.

Simple and beautiful - when the system is connected with multiple pipelines, it shall be kept parallel as far as possible and properly fixed with pipe clamps. In addition, during pipe laying, those parts requiring maintenance shall be avoided for routine maintenance and repair.

Safe and practical - short pipe connection is easy to cause fatigue damage. It is recommended to use transition joint instead of short pipe connection. When using the pipe clamp, it needs to be fixed, and the appropriate pipe clamp arrangement can properly eliminate the impact of vibration on the joint connection.