How Many Production Methods for Elbow Hose Fittings?

Max

2018-08-22 11:10:17

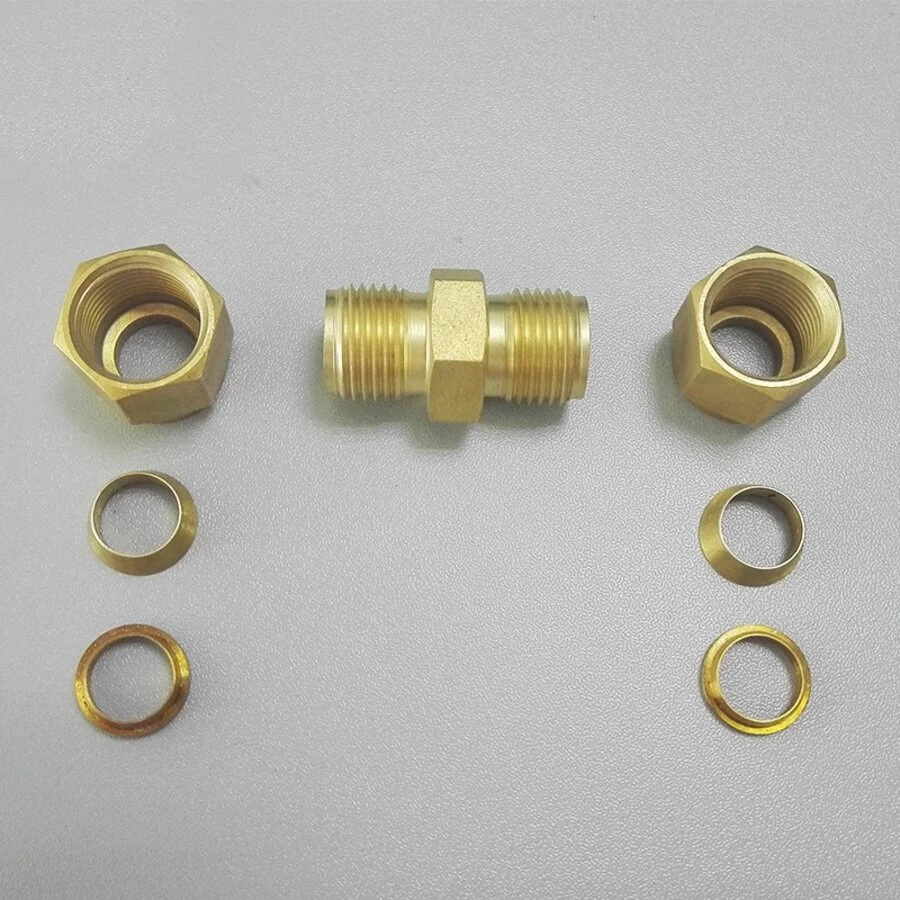

There are six common processing methods for elbow fittings, aluminium adapter, brass adapter, we will introduce you each main technology.

1.Bulging methods: One way is placing rubber in the tube, compressing on the top of tube with a punch, to make the tube protruding, then forming into required hose fittings. Another method is the hydraulic bulging forming. Filling liquid into the middle part of a tube, the tube can bulge into required shape by the liquid pressure, this method is mostly used in the production of wave pipes.

2.Stamping method: Use a tapered core in the punch to expanse the end of pipe to get the required size and shape.

3.Roller method: Placing a mandrel in the tube, then pushing the outer surface with a roller, which is used for the round edge processing.

4. Rolling method: Generally do not have mandrel, suitable for inside round edge processing of thick-walled tubes.

5.Bending method: There are three commonly methods, including extension method, stamping method, and roller method. For the roller method, there are 3-4 rollers, 2 fixed roller, and 1 adjustment roller to adjust fixed roller distance, the finished pipe is bending.

6. Forging method: use the forging machine to stretch the end of the pipe or a part of the pipe to reduce the diameter of pipe fittings, commonly used forging machine includes rotary, connecting rod, and roller types.

1.Bulging methods: One way is placing rubber in the tube, compressing on the top of tube with a punch, to make the tube protruding, then forming into required hose fittings. Another method is the hydraulic bulging forming. Filling liquid into the middle part of a tube, the tube can bulge into required shape by the liquid pressure, this method is mostly used in the production of wave pipes.

2.Stamping method: Use a tapered core in the punch to expanse the end of pipe to get the required size and shape.

3.Roller method: Placing a mandrel in the tube, then pushing the outer surface with a roller, which is used for the round edge processing.

4. Rolling method: Generally do not have mandrel, suitable for inside round edge processing of thick-walled tubes.

5.Bending method: There are three commonly methods, including extension method, stamping method, and roller method. For the roller method, there are 3-4 rollers, 2 fixed roller, and 1 adjustment roller to adjust fixed roller distance, the finished pipe is bending.

6. Forging method: use the forging machine to stretch the end of the pipe or a part of the pipe to reduce the diameter of pipe fittings, commonly used forging machine includes rotary, connecting rod, and roller types.