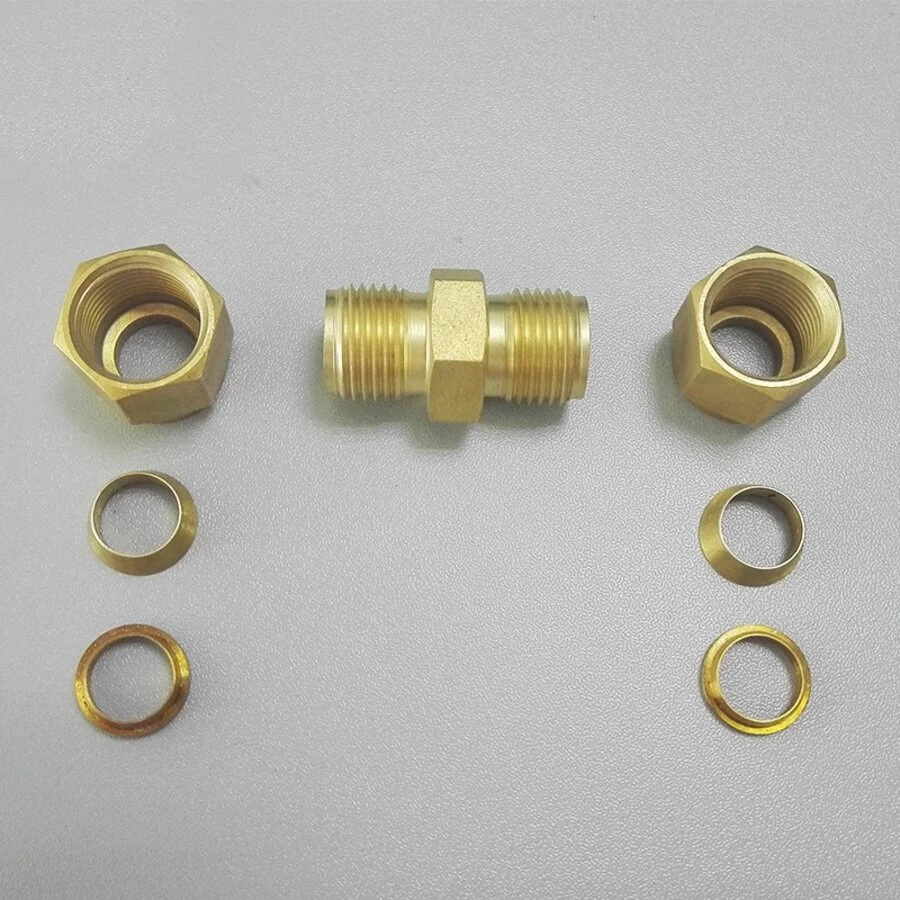

Joint application YC-LOK / tube

Jason

2020-05-20 14:26:05

The pipe joint is a connection tool between pipes and a removable connection point between parts and pipes. It plays an indispensable role in pipe fittings and is one of the two main components of the hydraulic pipe. The pipe joint is used for the straight connection of the instruments and socket or threaded welding is used. It is mainly used for the installation and disassembly of small diameter low pressure pipes or for the final adjustment of pipes with threaded fittings. The shape of the structure must be a sealing structure in metal contact, the sealing structure of the gasket is usually used for the transport of water, oil, gas and other general pipes and its material is malleable cast iron. In addition, the usage requirements and the price are also factors to consider in the selection.

There are many types of pipe joints. Common pipe joints can be divided into hard pipe joints and flexible pipe joints. According to the connection mode between the pipe joint and the pipe, the hard pipe joint is divided into flared type, ferrule type and welding type, and the hose joint is mainly a-type rubber tube joint. compression.

In the hydraulic system, the connection method of the pipe and joint is also different. The screw at the end of the tube adopts the connecting thread. The tapered thread is mainly used in the medium and low pressure hydraulic system due to its tightening and sealing operation of the vertebral body of polytetrafluoroethylene and other materials. The sealing effect of the fine thread is very good, which is often used in the high pressure system, but the combined washer or O-ring is needed to seal the end face, sometimes a copper washer is also needed. The utility model is best suited for connecting thick-walled pipes and components mainly include a connector, a connecting pipe and a nut. During use, the joint body is incorporated into the target body and the end face is sealed with the gasket. The rubber gasket is used between the body of the joint and the connection tube, sometimes the spherical seal is also used.

Since the pipe joint is a kind of removable connector, it must meet the requirements of stable connection, strong seal, reasonable size, reduced pressure loss, good process performance and meet convenient disassembly and assembly requirements. Therefore, do not look down on those small pipe joints, because only its existence can support the existence of the entire hydraulic system.

There are many types of pipe joints. Common pipe joints can be divided into hard pipe joints and flexible pipe joints. According to the connection mode between the pipe joint and the pipe, the hard pipe joint is divided into flared type, ferrule type and welding type, and the hose joint is mainly a-type rubber tube joint. compression.

In the hydraulic system, the connection method of the pipe and joint is also different. The screw at the end of the tube adopts the connecting thread. The tapered thread is mainly used in the medium and low pressure hydraulic system due to its tightening and sealing operation of the vertebral body of polytetrafluoroethylene and other materials. The sealing effect of the fine thread is very good, which is often used in the high pressure system, but the combined washer or O-ring is needed to seal the end face, sometimes a copper washer is also needed. The utility model is best suited for connecting thick-walled pipes and components mainly include a connector, a connecting pipe and a nut. During use, the joint body is incorporated into the target body and the end face is sealed with the gasket. The rubber gasket is used between the body of the joint and the connection tube, sometimes the spherical seal is also used.

Since the pipe joint is a kind of removable connector, it must meet the requirements of stable connection, strong seal, reasonable size, reduced pressure loss, good process performance and meet convenient disassembly and assembly requirements. Therefore, do not look down on those small pipe joints, because only its existence can support the existence of the entire hydraulic system.