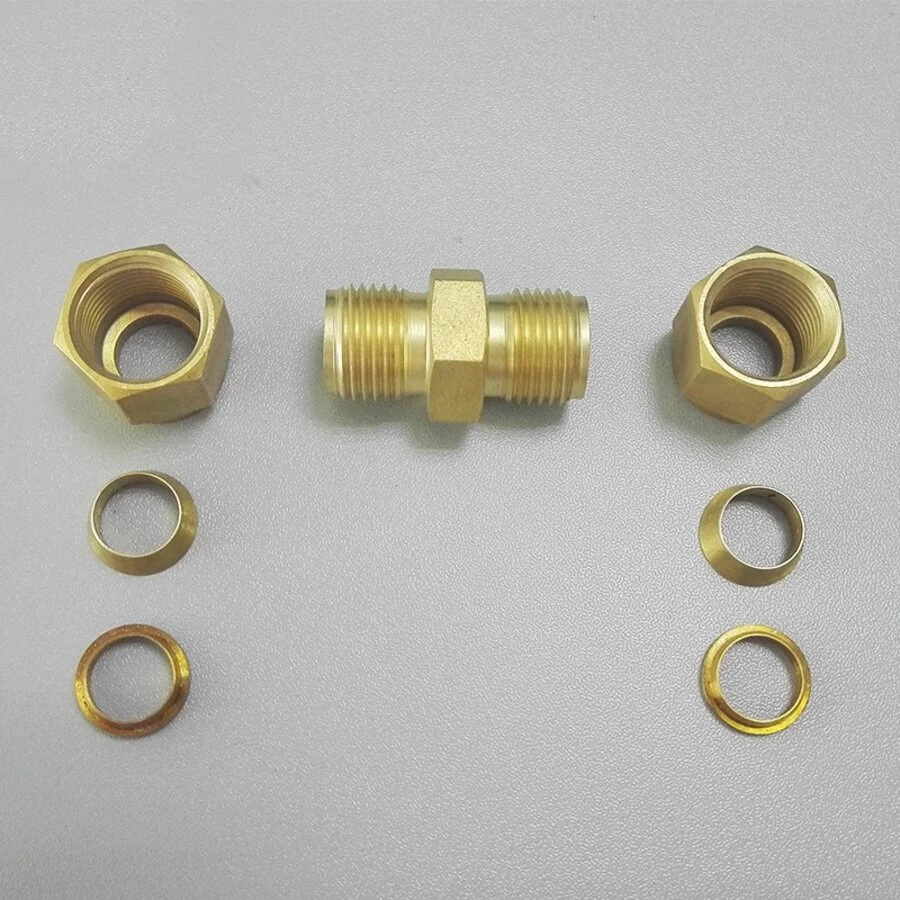

Rubber hose joint

When we use different types of hose, we need to equip it with a special joint to make it normal use. The hose joint is the part connecting the hose. Generally, there are many types, including with 24° flaring type sleeve joint, with spherical joint or with the same Angle conical joint, with sleeve type pipe connection joint, with 60° conical Angle connection joint, hollow hose screw connection joint, with sealing groove and without sealing groove thread connection joint, etc.

Two, how to connect the rubber hose joint

The connection of the rubber hose joint and the rubber hose is generally completed by the rubber hose clamping machine. First, the rubber hose is fed according to the required size, then the rubber hose is peeled, and then the rubber hose joint is installed, and finally the rubber hose clamping machine is used to press the specific steps are as follows:

1, choose the appropriate hose, hose size cutting.

2. The outer rubber at both ends of the rubber hose is peeled off.

3. Choose the right type of hose joint.

4. Install the joint core rod (need to be stained with oil) and install the hose joint jacket in turn.

5, the pressure machine, pay attention to choose the right amount of pressure.

6. After the compression is completed, clean the rubber lining of the hose, and then install the dustproof cap, sealing ring and retaining ring.

Three, how to ensure the sealing of the hose joint and the hose connection

The connection of the hose joint and the hose is very simple, but to ensure the sealing of the hose joint and the hose is very key, so how to seal the hose joint and the hose connection?

Generally speaking, no matter there are many kinds of rubber hose joints, we should choose how to use the transition joint according to the types of rubber hose joints. If the hose is an ordinary water pipe, it is necessary to use the transition joint for one internal tooth, one inserted water pipe, and then fixed with the throat hoop. If the two ends of the rubber hose are internal teeth, it is necessary to use the transition joint for an internal tooth and an external tooth. If the two ends of the rubber hose are external teeth, it is necessary to pass through the transition joint to the internal teeth.

General hydraulic quick change joint is to withstand high pressure, therefore, in most cases is the use of high pressure oil pipe, oil pipe two ends in most cases is to do internal teeth, so directly can; As for the hydraulic joint, it is not necessary to seal with other rubber rings, and the product itself is concave at one end and convex at the other end, and it can be completely sealed after connection.