Improper operation of ferrule type pipe joint will cause leakage and affect the use

Jason

2020-08-14 15:48:46

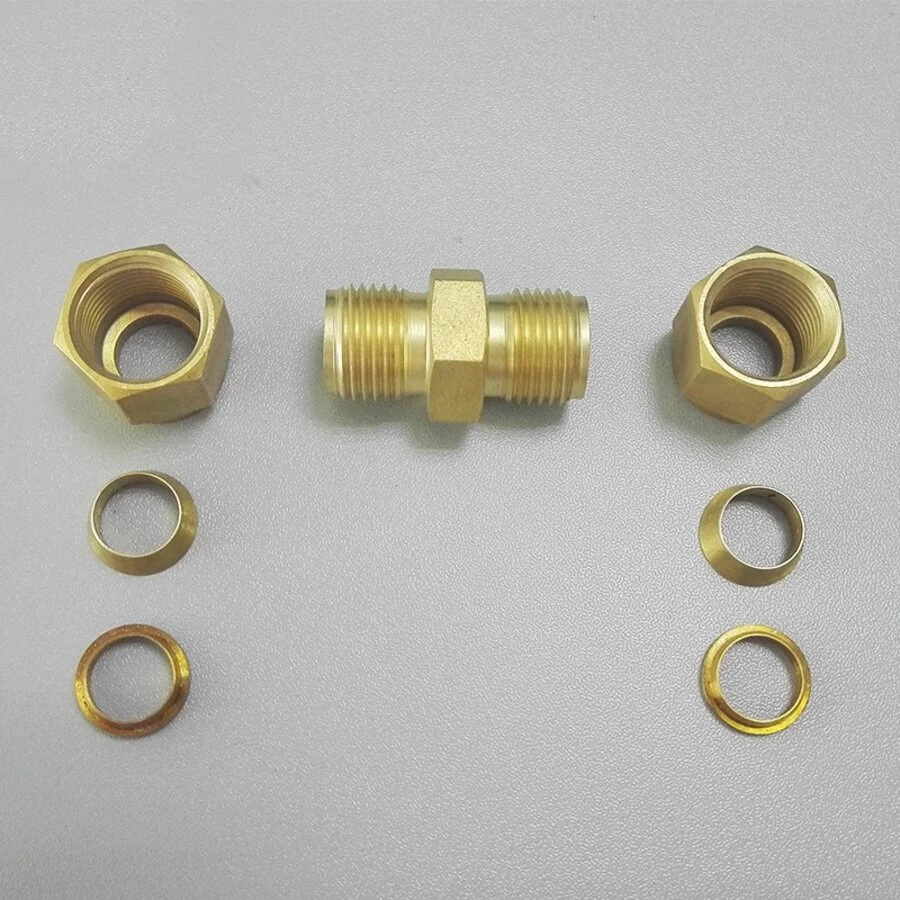

In fact, the ferrule pipe joint has the advantages of simple structure, convenient use and no welding. However, in the medium and high pressure hydraulic system, if the operation is improper, it will often cause leakage, which will affect its popularization and use.

Precautions for ferrule type pipe joint: it is forbidden to add fillers such as sealant. In order to get a better sealing effect, the hydraulic components are blocked by the sealing agent. When connecting the pipeline, the pipe should have enough deformation allowance to avoid the pipe being subjected to tensile force. When connecting the pipeline, the side force should be avoided. If the lateral force is too large, the sealing will not be tight. When connecting the pipeline, it should be good at one time to avoid multiple disassembly, otherwise the sealing performance will become worse.

Pre assembly of ferrule pipe joint:

Preassembly is the most important part of ferrule pipe joint, which directly affects the reliability of sealing. Generally, special pre heater is needed, and the joint with small diameter can be preassembled on the vise. The main types of ferrule type pipe joint are ferrule type straight pipe joint, ferrule type end, straight through connector and ferrule type tee joint. Even if it is a batch of goods from the same manufacturer, the depth of the conical hole on the joint body is often different, resulting in leakage, which is often ignored. The correct way is to connect one end of the pipe with what kind of joint body, and the corresponding connection end is preassembled with the same type of joint, so as to avoid leakage problems to the greatest extent.

The end face of the pipe should be flush. After the pipe is sawn, it should be polished and leveled on the grinding wheel and other tools, deburred, cleaned and cleaned with high-pressure air before use. During preassembly, the coaxiality of the pipe and the joint body should be kept as far as possible. If the pipe deflection is too large, the sealing failure will also be caused. The preloading force should not be too large, and the inner edge of the ferrule should be inserted into the outer wall of the pipe, and the ferrule should not be deformed obviously. When connecting the pipeline, assemble according to the specified tightening force.

Installation of ferrule type pipe joint: acid pickling treatment shall be carried out for the pipe requiring acid pickling as required; the pipe shall be cut off by sawing machine or special pipe cutting machine according to the required length; the burr, metal chips and dirt inside and outside the pipe end shall be removed; the antirust agent and dirt of the pipe joint shall be removed; the roundness of the pipe shall be ensured at the same time Insert the ferrule into the pipe successively, and the front edge (small diameter end) of the ferrule shall be at least 3mm away from the pipe opening, and then insert the pipe into the taper hole in the joint until it is pushed up; slowly tighten the nut, and at the same time rotate the pipe until it is still, and then tighten the nut for 2 / 3 ~ 4 / 3 turn; disassemble and check whether the ferrule has cut into the pipe and whether the position is correct. The ferrule is not allowed to move axially, but can be slightly rotated; re tighten the nut after passing the inspection.

Precautions for ferrule type pipe joint: it is forbidden to add fillers such as sealant. In order to get a better sealing effect, the hydraulic components are blocked by the sealing agent. When connecting the pipeline, the pipe should have enough deformation allowance to avoid the pipe being subjected to tensile force. When connecting the pipeline, the side force should be avoided. If the lateral force is too large, the sealing will not be tight. When connecting the pipeline, it should be good at one time to avoid multiple disassembly, otherwise the sealing performance will become worse.

Pre assembly of ferrule pipe joint:

Preassembly is the most important part of ferrule pipe joint, which directly affects the reliability of sealing. Generally, special pre heater is needed, and the joint with small diameter can be preassembled on the vise. The main types of ferrule type pipe joint are ferrule type straight pipe joint, ferrule type end, straight through connector and ferrule type tee joint. Even if it is a batch of goods from the same manufacturer, the depth of the conical hole on the joint body is often different, resulting in leakage, which is often ignored. The correct way is to connect one end of the pipe with what kind of joint body, and the corresponding connection end is preassembled with the same type of joint, so as to avoid leakage problems to the greatest extent.

The end face of the pipe should be flush. After the pipe is sawn, it should be polished and leveled on the grinding wheel and other tools, deburred, cleaned and cleaned with high-pressure air before use. During preassembly, the coaxiality of the pipe and the joint body should be kept as far as possible. If the pipe deflection is too large, the sealing failure will also be caused. The preloading force should not be too large, and the inner edge of the ferrule should be inserted into the outer wall of the pipe, and the ferrule should not be deformed obviously. When connecting the pipeline, assemble according to the specified tightening force.

Installation of ferrule type pipe joint: acid pickling treatment shall be carried out for the pipe requiring acid pickling as required; the pipe shall be cut off by sawing machine or special pipe cutting machine according to the required length; the burr, metal chips and dirt inside and outside the pipe end shall be removed; the antirust agent and dirt of the pipe joint shall be removed; the roundness of the pipe shall be ensured at the same time Insert the ferrule into the pipe successively, and the front edge (small diameter end) of the ferrule shall be at least 3mm away from the pipe opening, and then insert the pipe into the taper hole in the joint until it is pushed up; slowly tighten the nut, and at the same time rotate the pipe until it is still, and then tighten the nut for 2 / 3 ~ 4 / 3 turn; disassemble and check whether the ferrule has cut into the pipe and whether the position is correct. The ferrule is not allowed to move axially, but can be slightly rotated; re tighten the nut after passing the inspection.