hydraulic Tube fittings with Cutting ring

Jason Gao

2019-11-26 15:09:36

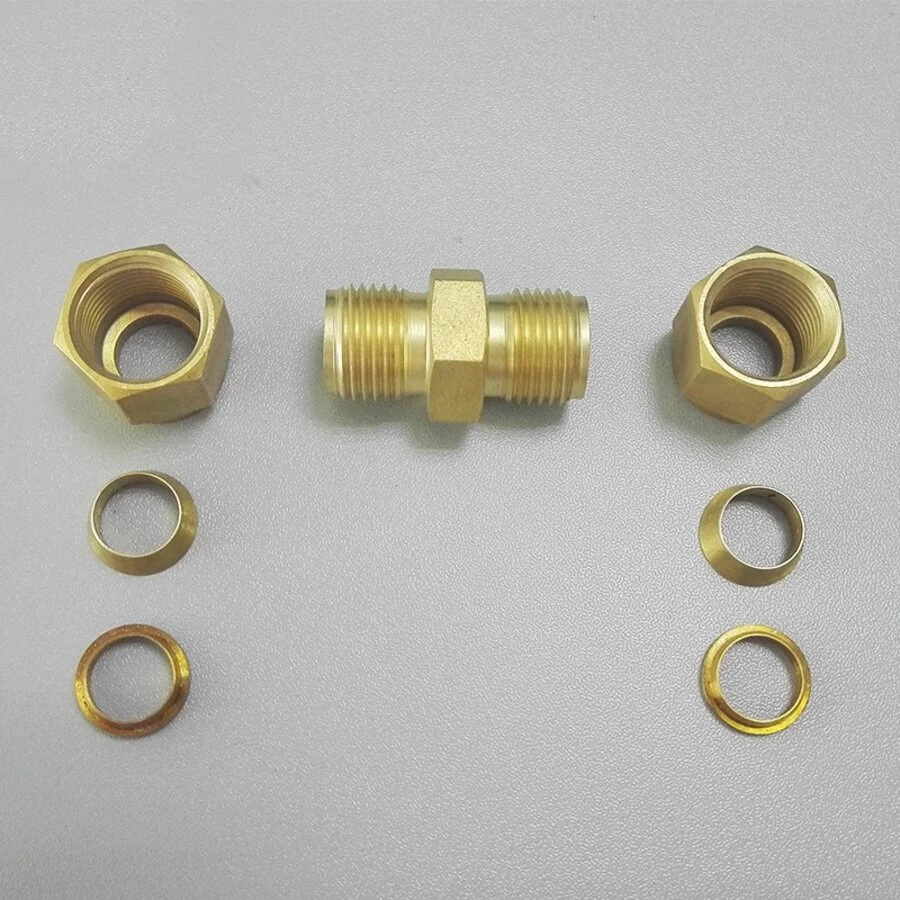

A single cutting ring has only one cutting ring , and the double has two cutting rings combinations.

Double ferrule fittings are suitable for: petroleum, chemical, metallurgy, pharmaceutical, instrumentation, machinery parts, power industry. The double ferrule type pipe joint is in the form of a cone, and the plunging angle of the ferrule has a double seal. The sealing performance of the double ferrule type pipe joint has high pressure bearing capacity and anti-vibration and anti-vibration performance. The pipe can be sealed normally even if it has scratches. The double ferrule type pipe joint can still resist corrosion and high pressure vibration. Normal use.

The joint material is generally stainless steel, nylon, copper polytetrafluoroethylene.

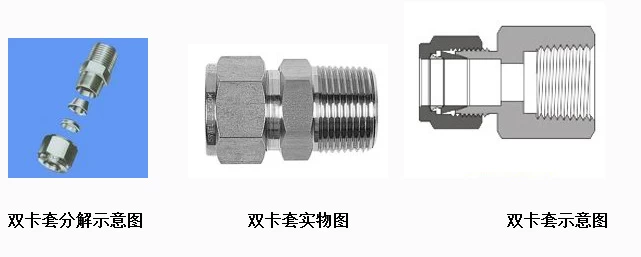

Schematic description of the sleeve joint

The connection principle of the sleeve type pipe joint is that the sharp inner edge of the ferrule gradually cuts into the outer wall of the steel pipe under the action of the increasing tightening torque, thereby achieving the purpose of reliably sealing the pipe joint.

1 Simple structure, reliable sealing performance, convenient use, excellent manufacturing, light and beautiful appearance.

2 No need to add washers, no welding, material saving, and good performance in repeated assembly and disassembly.

3. Since the tube joint is not welded, the influence of pipe impurities on system performance is reduced. Therefore, the ferrule type pipe joint is increasingly widely used in the hydraulic and pneumatic equipment pipelines with oil, gas and medium. It is especially suitable for occasions where there is danger of burning, high altitude operation and frequent assembly and disassembly.

The structure of the ferrule fitting is mainly composed of a joint body having a 24 ゚ tapered hole, a ferrule with a sharp inner edge, and a nut for pressing. When the nut is tightened, the ferrule is pushed into the 24 ゚ cone hole and deformed accordingly, so that the cutting edge of the ferrule cuts into the steel pipe and forms an annular grooving, thereby sealing. Because the ferrule is elastic, it can withstand large impacts and prevent loosening.

Double ferrule fittings are suitable for: petroleum, chemical, metallurgy, pharmaceutical, instrumentation, machinery parts, power industry. The double ferrule type pipe joint is in the form of a cone, and the plunging angle of the ferrule has a double seal. The sealing performance of the double ferrule type pipe joint has high pressure bearing capacity and anti-vibration and anti-vibration performance. The pipe can be sealed normally even if it has scratches. The double ferrule type pipe joint can still resist corrosion and high pressure vibration. Normal use.

The joint material is generally stainless steel, nylon, copper polytetrafluoroethylene.

Schematic description of the sleeve joint

The connection principle of the sleeve type pipe joint is that the sharp inner edge of the ferrule gradually cuts into the outer wall of the steel pipe under the action of the increasing tightening torque, thereby achieving the purpose of reliably sealing the pipe joint.

1 Simple structure, reliable sealing performance, convenient use, excellent manufacturing, light and beautiful appearance.

2 No need to add washers, no welding, material saving, and good performance in repeated assembly and disassembly.

3. Since the tube joint is not welded, the influence of pipe impurities on system performance is reduced. Therefore, the ferrule type pipe joint is increasingly widely used in the hydraulic and pneumatic equipment pipelines with oil, gas and medium. It is especially suitable for occasions where there is danger of burning, high altitude operation and frequent assembly and disassembly.

The structure of the ferrule fitting is mainly composed of a joint body having a 24 ゚ tapered hole, a ferrule with a sharp inner edge, and a nut for pressing. When the nut is tightened, the ferrule is pushed into the 24 ゚ cone hole and deformed accordingly, so that the cutting edge of the ferrule cuts into the steel pipe and forms an annular grooving, thereby sealing. Because the ferrule is elastic, it can withstand large impacts and prevent loosening.